-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com1.Introduction

Battery rolling machines, also known as battery electrode roller press machines, play a crucial role in the production process of lithium-ion batteries. These machines are designed to enhance the quality and performance of battery electrodes by applying precise rolling pressure to the electrode sheets. This article will delve into the application and working principle of battery rolling machines, accompanied by a conceptual diagram to illustrate the process.

2. Application

Battery rolling machines are primarily used in the manufacturing of lithium-ion batteries, specifically during the electrode processing stage. The electrodes, consisting of a coated foil (either copper or aluminum) with an active material layer, undergo a series of processes including coating, drying, and finally, rolling. The rolling process is essential for several reasons:

Enhancing Adhesion: It strengthens the bond between the active material and the foil, preventing delamination during electrolyte immersion or battery operation.

Improving Surface Quality: It ensures a smooth and flat surface, minimizing the risk of short circuits caused by burrs puncturing the separator.

Increasing Energy Density: By compacting the electrode material, the volume is reduced, leading to higher energy density and improved battery performance.

Working Principle

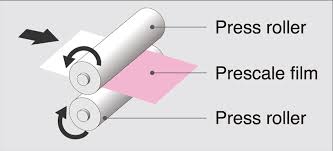

The working principle of a battery rolling machine revolves around the application of controlled pressure to the electrode sheets. The machine typically consists of two rollers, one stationary and the other driven by a motor. The electrode sheet is fed between these rollers, where it undergoes a rolling process.

Steps in the Rolling Process

Feeding: The electrode sheet, which has been coated and dried, is fed into the rolling machine. The sheet is typically in a semi-solid, granular state, with some degree of dispersion and fluidity.

Rolling: As the sheet enters the nip between the rollers, it is subjected to a combination of vertical and horizontal pressures. The vertical pressure compacts the active material particles, while the horizontal pressure aids in their lateral displacement and rearrangement.

Compaction and Deformation: The active material particles undergo both displacement and deformation during the rolling process. Initially, gaps between particles are filled, and then, as the pressure increases, the particles themselves deform, leading to a more densely packed electrode.

Exit and Collection: After rolling, the electrode sheet exits the machine with a smoother surface and increased density. It is then collected for further processing or assembly into batteries.

Key Factors Affecting Rolling Performance

Roller Diameter and Geometry: The diameter and geometry of the rollers affect the bite angle and the distribution of pressure on the electrode sheet.

Roller Material and Surface Roughness: The material and surface finish of the rollers can impact the quality of the rolled electrode, including its surface roughness and adhesion strength.

Rolling Speed and Pressure: The speed and pressure applied during rolling must be carefully controlled to achieve the desired electrode density and surface quality.

Environmental Conditions: Factors such as humidity and temperature can also influence the rolling process and the final properties of the electrode.

Conclusion

Battery rolling machines are essential tools in the production of high-performance lithium-ion batteries. By applying precise rolling pressure to electrode sheets, these machines enhance adhesion, improve surface quality, and increase energy density. Understanding the working principle and key factors affecting rolling performance is crucial for optimizing the production process and ensuring the quality of the final battery product.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: