-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com

2. Types and configurations of battery roller machines

2.1 Horizontal battery roller machine

2.2 Vertical battery roller machine

2.3 Multi stage battery roller machine

3. Operation steps of battery roller machine

4.2 Adhere to operating procedures

4.4 Regular inspection and maintenance

1. Introduction

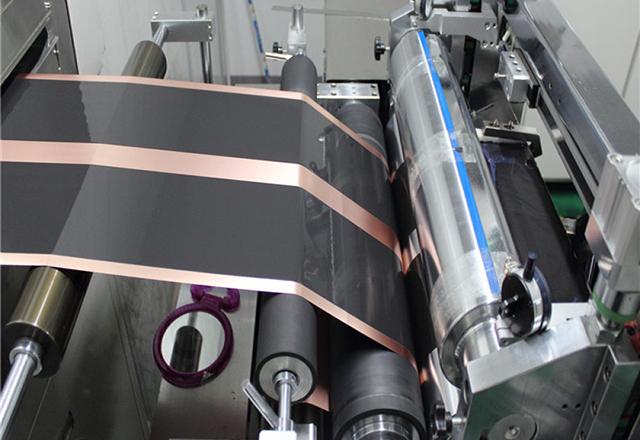

In the battery manufacturing industry, batteries play a crucial role in rolling machines. It is mainly used for rolling, compressing, and shaping battery electrodes to ensure uniform distribution and tight compaction of the electrodes, thereby improving the efficiency, capacity, and safety of the battery. The design of battery roller machines is usually based on precise mechanical principles and advanced control systems to achieve precise treatment of electrodes.

2. Types and configurations of battery roller machines

2.1. Horizontal battery roller machine:

This type of machine adopts horizontally arranged roller shafts, suitable for large-scale production, and has high throughput.

Usually equipped with an automatic feeding system, it can continuously feed electrodes into the roller shaft for processing.

The clearance and pressure of the roller shaft can be adjusted through a precise control system to meet the processing needs of different electrodes.

2.2. Vertical battery roller machine:

The vertically arranged roller shaft makes the machine more compact and suitable for handling smaller or special shaped electrodes.

Vertical layout also helps to reduce material waste and dust pollution.

It also has a precise control system to ensure the accuracy and consistency of electrode processing.

2.3. Multi stage battery roller machine:

By combining multiple roller shaft stages, multiple rolling and compression of the electrodes are achieved to achieve higher electrode density and uniformity.

Multi stage design allows for the application of different pressures and speeds at different stages to meet the processing needs of different materials.

Usually equipped with advanced monitoring systems for real-time monitoring of electrode quality and processing.

3. Operation steps of battery roller machine

Check if the machine is in good condition, including the roller shaft, transmission system, control system, etc.

Clean up debris and dust inside and outside the machine to ensure a clean working environment.

Prepare the electrode materials to be processed and check if their quality and specifications meet the requirements.

Press the power button to start the control system of the battery on the roller machine.

According to the characteristics of electrode materials and processing requirements, set appropriate parameters such as roller shaft clearance, pressure, and speed.

Check if the machine is running properly and perform necessary preheating or calibration operations.

Feed the electrode material between the roller shafts to ensure that the electrodes are evenly distributed and tightly adhere to the surface of the roller shaft.

Start the roller shaft rotation to roll and compress the electrodes. During the processing, closely monitor the changes in the electrodes and adjust parameters as needed.

After processing, remove the electrode from between the roller shafts and conduct a preliminary quality inspection.

Conduct a detailed quality inspection on the processed electrodes, including thickness, density, uniformity, and other indicators.

Use professional equipment to measure and analyze electrodes to ensure they meet product standards and customer requirements.

Mark and record the unqualified electrodes, and take corresponding treatment measures.

After each processing is completed, promptly clean the residues and dust inside and outside the machine.

Regularly inspect the wear and damage of components such as roller shafts, transmission systems, and control systems, and carry out necessary repairs and replacements.

Regular maintenance and upkeep of the machine to extend its service life and maintain stable performance.

4. Safety precautions

4.1 Wear protective equipment: When operating the battery roller machine, protective gloves, goggles, and earplugs must be worn to prevent accidental injury.

4.2 Adhere to operating procedures: Strictly follow the operating procedures and do not change parameters or engage in illegal operations without authorization.

4.3 Keep the machine clean: Regularly clean the internal and external residues and dust of the machine, and maintain a clean and orderly working environment.

4.4 Regular inspection and maintenance: Regularly inspect and maintain the machine to ensure its normal operation and stable performance.

4.5 Emergency stop: In the event of an emergency or machine malfunction, the emergency stop button should be immediately pressed and the power should be cut off to ensure the safety of personnel and equipment.

Battery roller crusher, also known as double roller crusher or roller crusher, has a wide range of applications. Firstly, battery roller machines (especially lithium battery roller machines) play an important role in the battery industry, mainly used in the production process of electronic products such as lithium-ion batteries, polymer lithium-ion batteries, and solid-state batteries. Its main function is to combine and fix the positive and negative electrodes of the battery cell through the rolling process. Different types of battery cells require different roller presses because they require different rollers and roller pressures.

In addition, battery roller presses (or more generally, roller presses) are also widely used in industries such as chemical and electronics. In the chemical industry, roller presses can be used for extrusion processing of raw materials to meet the required process requirements. Especially in the battery industry, the battery specific roller press is specifically designed for the lithium-ion battery rolling process. Due to the high precision required for pole plate rolling, the roller press needs to have characteristics such as high hardness, uniform pressure, easy adjustment, and high precision.

In addition to the battery and chemical industries, battery roller machines (or sand making roller machines) are also suitable for crushing in industries such as mining, cement, highways, railways, coal, metallurgy, and building materials. It can crush various stone materials with compressive strength less than 160 megapascals, such as river pebbles, calcite, quartz, marble, pebbles, bentonite, iron ore, bluestone, mountain stones, water slag, limestone, weathered sand, diabase, granite, basalt, etc.

Overall, the application range of battery roller machines is wide, not limited to the battery industry, but also includes multiple industries such as chemical, mining, cement, highways, railways, coal, metallurgy, building materials, etc.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: