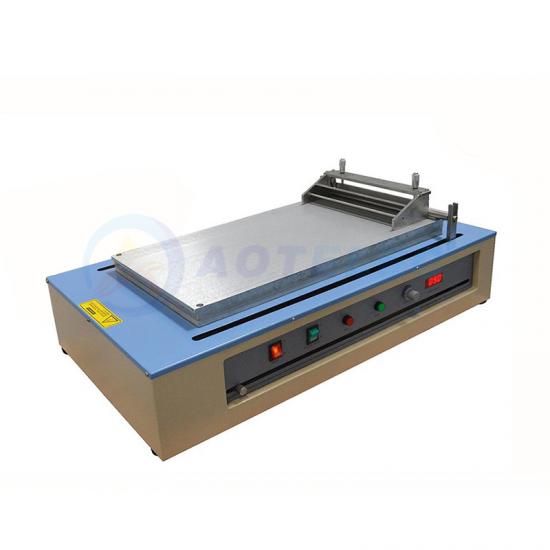

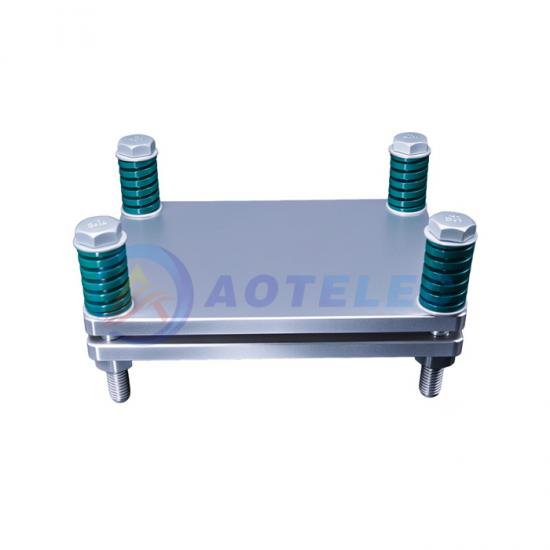

Vertical electric roller press machine for battery electrode calendering

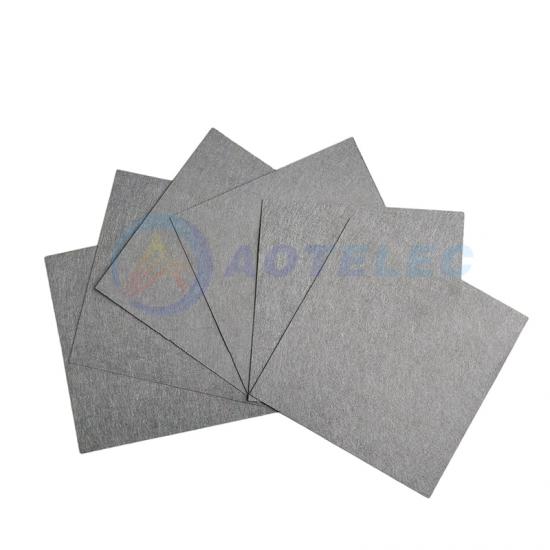

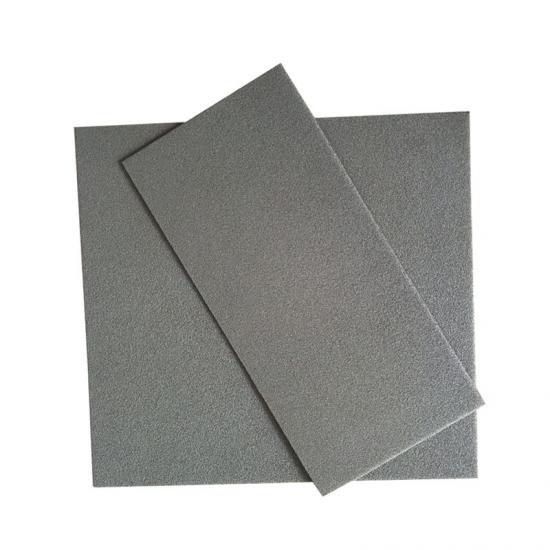

This equipment is mainly used for electric rolling press of battery materials, a few precious metal materials like gold and silver, nonferrous materials like copper and aluminum in lab .

Features :

1. Hard chrome plated on surface.Material HRC62.

2. Transparent protective plate is designed for safety operation .

3. Press gap is adjustable .

4. Rolling speed , press thickness is adjustable .

Application :

Battery lab

Battery research

Lithium ion battery lab

Material research

Trial-production

|

Battery Lab Equipment of Electric Roller Press |

|||||||||||||||||

|

Item Name |

Battery material presser AOT-ERP-100 |

||||||||||||||||

|

Watt |

100W |

||||||||||||||||

|

Voltage |

220V |

||||||||||||||||

|

Roller material |

HRC62 |

||||||||||||||||

|

Roller diameter |

96mm |

||||||||||||||||

|

Ra |

>0.8um |

||||||||||||||||

|

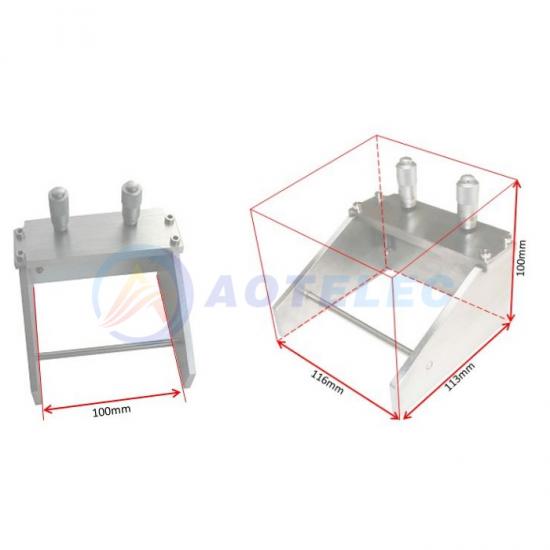

Press gap |

0-2mm adjusted |

||||||||||||||||

|

Rolling width |

0-100mm adjusted |

||||||||||||||||

|

Rolling speed |

0~40mm/s adjusted |

||||||||||||||||

|

Size |

L385mm*W245mm*H355mm |

||||||||||||||||

|

Weight |

60KG |

||||||||||||||||

|

|

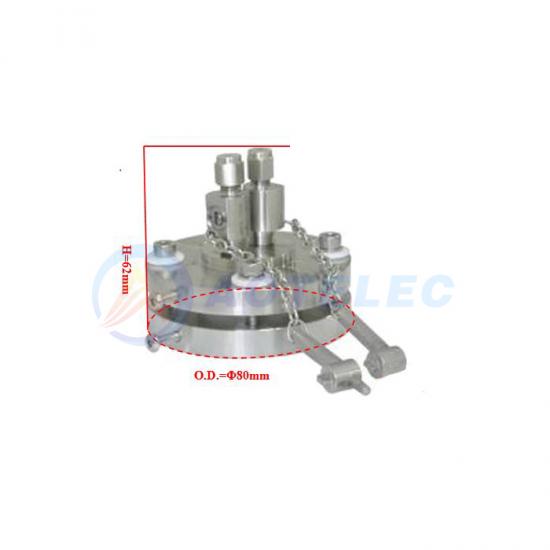

This roller is specially designed for battery R&D in terms of its advantages as affordable, compact and precise. 1 Must use acetone to clean and dry rollers' surfaces after each use to avoid rusting 2 Coated Rust-proof oil if machine were to be unused for a long period of time 3 The minimum thickness of the rolled sheet should depend on the physical property of the materials. Here are some results from our test:

Sample testing is available upon customer's request |

||||||||||||||||

Exhibition

Certificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported