-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com

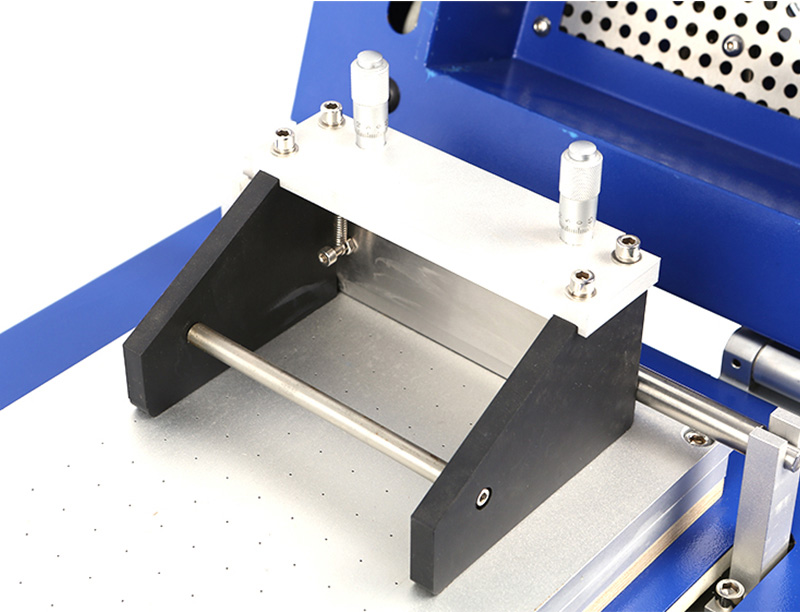

The battery coating machine is easy to operate and efficient. First, the operator needs to place the pole sheet to be coated in the feed port of the coating machine to ensure that the pole sheet is smooth and free of impurities. Then, start the coating machine, through the precision control system, the coating machine in accordance with the preset parameters and speed, the active substance evenly coated on the surface of the pole. During the coating process, the coating machine can monitor the coating thickness and uniformity in real time to ensure that the coating quality meets the standard requirements. After coating is completed, the coating machine automatically outputs the pole sheet to the next process, and the entire operation process is automated and continuous, which greatly improves the production efficiency.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: