-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.comBattery Sorting Machine: A Vital Tool for the Battery Industry

Introduction

In the rapidly evolving battery industry, the demand for high-performance and reliable batteries is ever-increasing. To meet this demand, battery manufacturers rely on sophisticated equipment, including battery sorting machines, to ensure the quality and consistency of their products. This article explores the significance, workings, types, benefits, challenges, and future prospects of battery sorting machines.

Significance of Battery Sorting Machines

Battery sorting machines play a crucial role in the battery manufacturing process. They are responsible for separating batteries based on various parameters such as capacity, voltage, internal resistance, and size. This sorting process is essential to ensure that batteries with similar characteristics are grouped together, enabling manufacturers to produce batteries that meet specific performance requirements.

Working Principle of Battery Sorting Machines

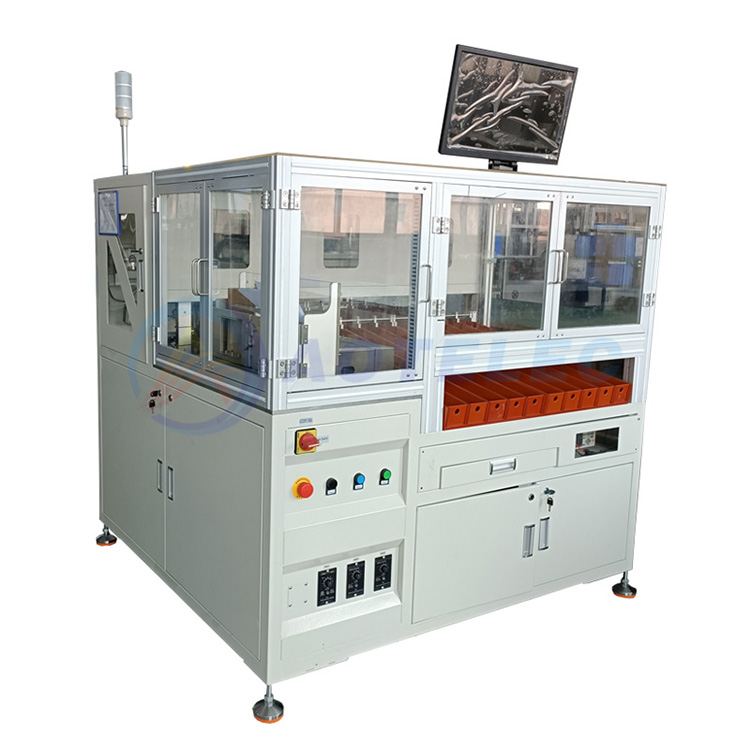

Battery sorting machines operate on the principle of automated testing and classification. These machines utilize various sensors and measuring devices to assess the electrical properties of each battery. Once the batteries are tested, the machine uses sophisticated algorithms to categorize them into different groups based on the desired specifications.

The sorting process typically begins with the loading of batteries onto the machine's conveyor belt. As the batteries move along the belt, they are subjected to various tests such as capacity discharge, voltage measurement, and internal resistance analysis. The test results are then processed by the machine's control system, which determines the appropriate sorting category for each battery.

Types of Battery Sorting Machines

Battery sorting machines can be classified into several types based on their function, design, and the batteries they sort. Common types include:

Capacity Sorting Machines: These machines sort batteries based on their capacity, ensuring that batteries with similar energy storage capabilities are grouped together.

Voltage Sorting Machines: Voltage sorting machines separate batteries based on their voltage output, allowing manufacturers to produce batteries with specific voltage requirements.

Internal Resistance Sorting Machines: These machines assess the internal resistance of batteries, a key indicator of battery performance.

In addition, battery sorting machines can be further categorized as manual, semi-automatic, or fully automatic based on their level of automation.

Benefits of Using Battery Sorting Machines

Battery sorting machines offer numerous benefits to battery manufacturers: Improved Product Quality: Sorting batteries based on their characteristics ensures that batteries with similar performance are grouped together, leading to improved consistency and reliability.

Enhanced Efficiency: Automated sorting machines significantly reduce the time and labor required for battery sorting, increasing overall production efficiency.

Cost Savings: By reducing waste and improving product quality, battery sorting machines contribute to cost savings for manufacturers.

Challenges Facing Battery Sorting Machines

Despite their benefits, battery sorting machines face some challenges: Technological Complexity: Advanced battery sorting machines require sophisticated technology and expertise for their operation and maintenance.

Initial Investment: High initial investment costs can be a barrier for some small and medium-sized battery manufacturers.

Future Prospects

With the continued growth of the battery industry, battery sorting machines are expected to become even more advanced and efficient. Future developments may include the integration of artificial intelligence and machine learning technologies to improve sorting accuracy and efficiency. Additionally, the development of more environmentally friendly and sustainable battery sorting machines will be crucial to meeting the demands of the modern battery industry.

Conclusion

Battery sorting machines are indispensable tools for ensuring the quality and consistency of batteries produced in the battery industry. As technology continues to evolve, battery sorting machines are likely to become more advanced, efficient, and environmentally friendly, playing an even more crucial role in the future of battery manufacturing.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: