-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.comCapacity is the primary attribute of a battery, and insufficient cell capacity is also a common problem encountered during sample and mass production. This article mainly analyzes the problem of no capacity in battery cells. What is the reason for insufficient battery capacity?

When hearing that the battery cell capacity is insufficient, the first reaction should be to confirm whether there is indeed a problem of insufficient capacity. Simply put, first confirm whether the capacitor process is set incorrectly, such as high discharge current, short charging time of charging equipment, etc. If there is no problem with setting the capacitor step size, grid division is required after replacing the test point. Of course, for mass production and even samples, the probability of insufficient capacity caused by errors in the capacity distribution cabinet is very low, and generally batteries do have problems. If the capacity is still low after retesting, it can be confirmed that the problem of insufficient capacity does exist. After confirming the insufficient capacity of the battery cell, it is necessary to further confirm the frequency and severity of the insufficient capacity, and grasp the actual situation of the insufficient capacity as a whole. The samples are often a batch, but the production models are either "models with insufficient production capacity" or "models with occasional insufficient production capacity". For the former, analysis should focus on design, material selection, and mass production as the starting point and priority direction. For the latter, production line operation and process changes are given priority. After determining the frequency, it is also necessary to confirm the relatively unimportant severity, namely the proportion of insufficient cell capacity and the proportion of capacity below the required value. The confirmation of severity is more likely to provide a basis for the possible relaxation of production capacity specifications and the judgment of inventory shortages, while the analysis of the problem itself, although not as important as the frequency of confirmation, is still essential.

After fully understanding the actual situation of insufficient production capacity, it is necessary to start analyzing. For highly skilled professionals who have encountered the same problem, removing three batteries should be able to roughly determine the true reason for the insufficient battery capacity. But for ordinary people, a more systematic approach is needed. Before analyzing the system, you can dismantle the situation where the battery cells that were previously remeasured and fully charged have insufficient power and take a look at the interface. If there are no issues, it is likely due to the positive electrode coating being too light or insufficient design margin. If there is a problem with the interface, it may be due to manufacturing or design issues. Firstly, you need at least 8 batteries with insufficient capacity and 8 batteries with qualified capacity. Then randomly divide the batteries with insufficient capacity into two groups, namely group A with insufficient capacity and group B with insufficient capacity, and randomly divide the qualified batteries into two groups, namely group A and group B. Then discharge the two A-group batteries to a static voltage of approximately 3.0V. Then disassemble the batteries with insufficient capacity and qualified ones, vacuum bake the positive electrode plates at 85 ℃ or above for 24 hours, and weigh the negative electrode plates with insufficient capacity and qualified ones. If the weight of the electrode with insufficient capacity is significantly lower than the weight of the qualified positive electrode or lower than the process range, it can be basically judged that the insufficient capacity of the battery cell is caused by the light coating of the positive electrode. Firstly, although the first irreversible lithium source of the positive electrode may cause some weight loss, the total weight of the irreversible lithium source only accounts for about 5% of the positive electrode lithium source, which is less than 0.5% of the weight of the positive electrode sheet. The irreversible lithium source caused by the positive electrode light source shall not be less than 1% of the total weight of the electrode sheet.

During the baking process, the electrolyte cannot be completely dried, but the actual weight of the residual part is limited relative to the weight of the electrode plate. Overall, the error between the weight of the positive electrode plate after baking and the actual weight of the coil front plate is not more than 2%. Moreover, there is a comparison between the weight of positive electrode sheets with qualified capacity and the weight of electrode sheets with insufficient

Secondly, the same method is not applicable to the positive electrode because it will increase a lot of weight. However, we can provide the weight increase ratio of the positive electrode after the experiment, and then calculate the weight of the positive electrode in reverse to determine whether the insufficient capacity of the battery cell is caused by an excess of positive electrodes. If it is confirmed that the reason for the positive electrode being too light is due to insufficient capacity, then it will be lucky, but in fact, the probability of such luck is often just a coincidence. In this case, it is necessary to analyze the B group with insufficient capacity and the qualified B group. The B group battery needs to be fully charged and then disassembled to compare the differences in the negative electrode interface. A low discharge capacity is equivalent to a low charging capacity, which means that the negative electrode fully charged interface will be abnormal.

In fact, in most cases, as long as there is insufficient capacity, regardless of whether the battery is insufficient or qualified, similar abnormalities will appear on the interface, but to varying degrees. When recording the interface status of battery cells, it is also necessary to record the actual capacity of the corresponding battery cells. The final conclusion is roughly the same, that is, battery cells with insufficient and high capacitance have more severe interface abnormalities. The reasons for insufficient battery cell capacity: The reasons for insufficient battery capacity can be divided into two aspects: battery design and process. The matching of materials, especially the matching of positive electrode and electrolyte, has a significant impact on battery capacity. For a new negative electrode or electrolyte, if repeated testing reveals that the battery will precipitate lithium every time, resulting in insufficient capacity, it is likely that the material itself is not compatible. The reason for the mismatch may be that the SEI film formed during the formation process is not dense enough, too thick, or unstable, or it may be that the PC in the electrolyte peels off the graphite layer. It cannot be ruled out that the surface density of the designed battery is too high, which may cause the battery to be unable to adapt to high rate charging and discharging. Diaphragm is also a factor that may lead to insufficient capacity. For the case of using single-layer PP low-cost separators, manually wound battery separators will have wrinkles in the longitudinal direction at the middle position of each layer, and the negative electrode cannot be fully inserted into the wrinkles, which affects the battery capacity. Insufficient capacity design margin can also lead to insufficient capacity. Due to errors in positive and negative electrode coatings, separators, and the influence of adhesives on capacity, a certain capacity margin must be left in the design. When designing capacity margin, it is possible to first calculate that the battery capacity is exactly on the center line during all processes, and then leave a margin. Alternatively, the margin can be calculated after all factors that affect capacity have occurred below the limit value. Accurately evaluating the weight performance of the positive electrode under this system is crucial for new materials.

The capacity ratio, cut-off charging current, charging and discharging rate, and electrolyte type all affect the performance of the positive electrode. If the design value of the positive electrode is artificially increased in order to achieve the target capacity, it is actually equivalent to insufficient design capacity. There is no problem with the battery interface and the entire process data, but the battery capacity is insufficient. Therefore, new materials must pay attention to evaluating the accurate performance of the positive electrode. Different positive electrodes have different performance when matched with any negative electrode and electrolyte. Excessive negative electrode can also affect the performance of the positive electrode to a certain extent, thereby affecting the capacity of the battery. Continuing to add excess negative electrode at the lower limit where lithium deposition does not occur will increase the performance of the positive electrode by about 1% to 2%. Of course, even if it is increased, the larger the design capacity output, the better. The excess positive electrode still needs to ensure that lithium cannot precipitate. When the excess amount of positive electrode is too high, the performance of negative electrode will decrease again because more irreversible lithium is needed to form. Of course, the probability of this happening is almost non-existent. When the liquid injection amount is low, the corresponding liquid retention amount will also decrease. When the liquid retention of the battery cell is too small, the insertion and extraction of lithium ions in the positive and negative electrodes will be affected, resulting in a decrease in capacity. Although reducing the amount of liquid injection will lower the cost and process pressure, the premise of reducing the amount of liquid injection is that it cannot affect the performance of the battery. Of course, reducing the amount of liquid injected will only increase the likelihood of insufficient battery cells due to insufficient liquid retention, rather than an inevitable result. At the same time, the greater the difficulty of the model's liquid absorption, the more excess electrolyte should be used to ensure better contact with the electrode during the electrolyte penetration process. When the liquid retention capacity of the battery cell is insufficient, the positive and negative electrode plates will become relatively dry, and a thin layer of lithium deposition will occur on the negative electrode. This can serve as a factor causing low capacity due to insufficient liquid retention capacity. Analyzing the reasons for the shortage of battery cells: If the design experience or past batches have determined that the design will not cause the shortage in the battery manufacturing process, then process abnormalities are very suspicious. The light coating on the positive or negative electrode can directly lead to insufficient battery cells. When the coating on the positive electrode is light, the interface of the rechargeable battery will not be abnormal. At this point, it is necessary to determine the problem by drying and measuring the weight of the positive electrode sheet.

As a receptor for lithium ions, the positive electrode must provide more lithium intercalation sites than the positive electrode can provide lithium sources. Otherwise, excess lithium will deposit on the negative electrode surface, forming a relatively uniform layer of lithium deposition. As mentioned above, because the weight of the negative electrode sheet cannot directly remove the baking weight of the electrode sheet, an experiment can be conducted to find the weight increase ratio of the negative electrode sheet through the core of the coating weight to remove the baking weight of the negative electrode sheet. Another method is to compare the weight of the negative electrode of the battery or ternary lithium battery without analyzing the weight of the negative electrode of the lithium battery cell. If the relative weight of the negative electrode of a qualified battery is heavy, and there is a thin layer of lithium deposition on the surface of the negative electrode, then the possibility of insufficient negative electrode is very high. In addition, coating the positive and negative sides of the positive or negative electrode can also lead to deficiencies. Among them, the negative electrode mainly has a lighter coating on one side, because even if the positive electrode coating is heavier, although the weight performance will decrease, the total capacity will not decrease. On the contrary, it may even increase. If the process of the negative electrode is a misaligned coating, and the relative weight ratio of one side and two sides after baking is directly compared, as long as the data of the A-side coating is 6% lighter than that of the B-side, the problem can be basically concluded. Of course, if the problem of insufficiency is very serious and further inversion of the actual surface density of A/B planes is required. Rolling can damage the structure of the material, thereby affecting its capacity. The fundamental reason why a material has properties such as capacity and voltage is its molecular or atomic structure. When the rolling density of the positive electrode exceeds the technical value, the positive electrode sheet will be very bright after battery disassembly. If the positive electrode is compacted too much, the positive electrode sheet is prone to breakage after winding, which can also lead to shortages. However, due to the fact that crushing the positive electrode can cause the electrode sheet to break immediately when folded, and the rolling of the positive electrode itself requires a lot of pressure, the frequency of crushing the positive electrode is much lower than that of crushing the negative electrode. When the negative electrode is crushed, the surface of the negative electrode will form strip-shaped or block shaped lithium deposits, and the liquid retention of the battery cell will be significantly reduced. When the compaction further increases, the large area of lithium deposition increases, and the amount of lithium deposition also increases. The platinum on the surface of the battery appears in two colors, obvious and dry.

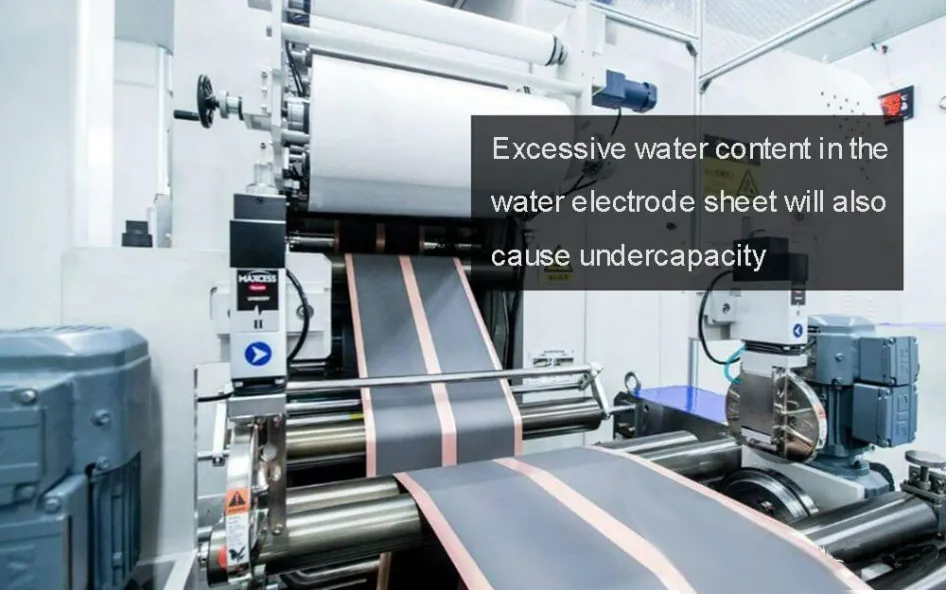

Excessive moisture content can also cause insufficient battery cell capacity. When the water content of the electrode before battery injection exceeds the standard, the dew point of the glove box is not qualified, the electrolyte water content exceeds the standard, and moisture is introduced into the secondary degassing seal, the battery may experience insufficient capacity. A small amount of water is required for battery formation, but when the water content exceeds a certain value, the excess water will damage the SEI film, consume lithium salts in the electrolyte, and thus reduce the capacity of the battery. Batteries with high moisture content will appear as small dark brown patches when fully charged or negatively charged. Conclusion Analysis: For battery cells with insufficient capacity, if there is confidence, dismantling a few cells with poor appearance can basically confirm the problem. If the volume loss is caused by insufficient capacity, a detailed report is needed, or if the reason for insufficient capacity is something that has never been seen before, it is necessary to resolutely conduct a detailed analysis from the aspects of collecting process data, comparing insufficient capacity with qualified battery cells, and improvement plans.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: