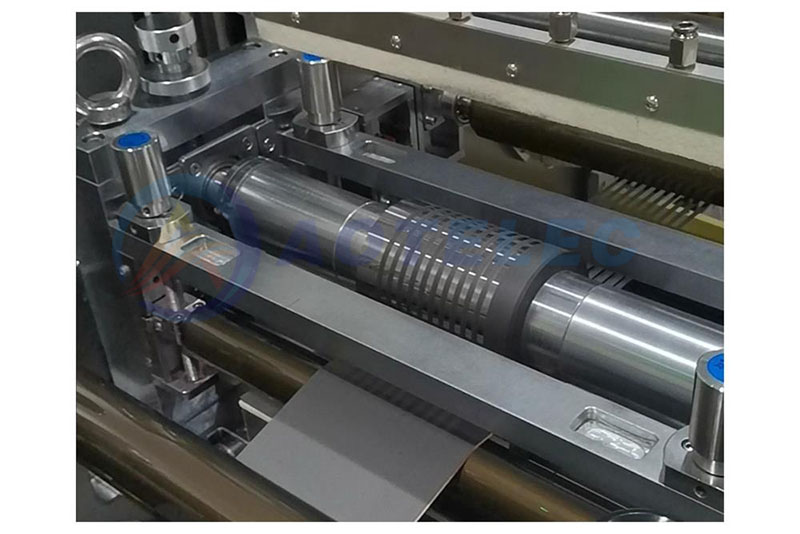

This equipment is used for the slitting process of lithium battery electrode coil, mainly suitable for cutting multiple narrow strips. The equipment has high cutting accuracy, adopts closed-loop tension control, and has a stable cutting structure. After cutting, the pole pieces have no defects such as ruffles, burrs, indentations, etc. Designed for the micro-batteries, typically, the Bluetooth batteries.

Functional Features:

1.The overall cantilever design of the equipment facilitates the retrieval, placement, threading, and maintenance of materials;

2.Closed loop control of unwinding tension, measurement of roll diameter, ensuring stable feeding, and early warning of material shortage;

3.The cutting blade holder is independently designed for easy maintenance and switching;

4.The cleaning structure design of the slitting knife facilitates blade maintenance and ensures slitting quality;

5.Four station winding to improve production efficiency;

6.Dust removal treatment at multiple stations before and after slitting to ensure the quality of the polarizer;

7.Low tension design for winding, ensuring stable slitting of narrow pole pieces;

8.The design of the winding traceability mechanism ensures the stability of slitting and winding.

Specification:

|

Product Name |

Battery Electrodes Slitting Machine |

|

Working Voltage |

380V AC, Three-phase, 50/60 Hz |

|

Cutting Speed |

0-40m/min |

|

Automatic Tension control |

0-100N,+/-2N |

|

Maximum Reeling Diameter |

350 mm |

|

Maximum Unreeling Diameter: |

450 mm |

|

Automatic unwinding correction |

accuracy ± 0.5mm |

|

Each electrode strip range |

3 - 10 mm width |

|

Total cutting width |

300 mm |

|

After cutting |

there are no ruffles, no indentations, no knife overprints, and no burrs on the appearance |

|

Weight |

2.5T |

IPv6 network supported

IPv6 network supported