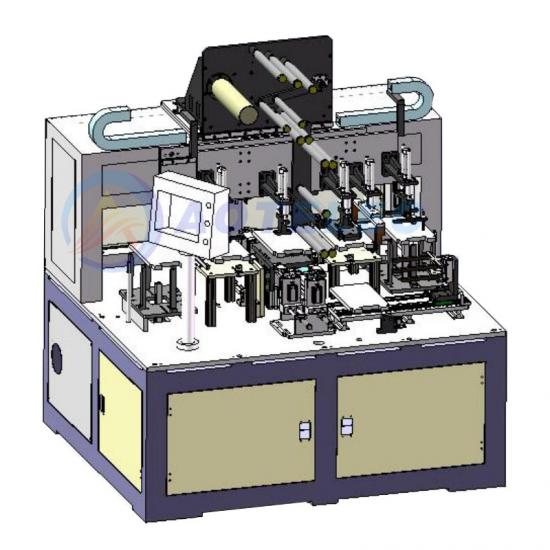

MSK-SFM-9-5L dual dispersing shaft vacuum planetary mixer is an efficient mixing device that integrates low-speed mixing and high-speed dispersion. It combines orbital and rotational motion to achieve thorough mixing of materials. It can be applied to the mixing process of various solvents and powders, such as the batching process of raw materials for lithium-ion batteries, tapes, solar energy, chemical industry, etc. The device is designed with integration, with good mixing uniformity and is convenient and easy to use.MSK-SFM-9-5L is an excellent tool for preparing LiCoO3, LiFePO4, LiNCMO2, and ceramic slurries and provides much better results in dispersion and uniformity.

|

Working Voltage |

Single phase AC220V ± 10%, frequency 50Hz, power approximately 5.5KW |

|

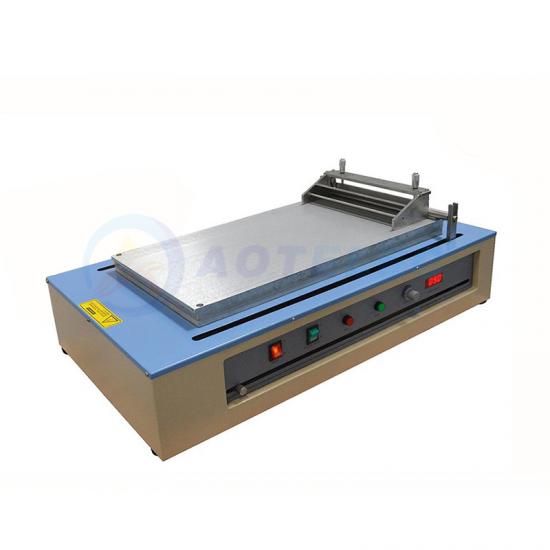

Mxing Method |

Revolution+rotation, dual stirring shaft+dual dispersing shaft (4 dispersing disks)+1 scraping blade (PTFE) |

|

Control Method |

The functions of variable frequency speed regulation, temperature control, spotlight, lifting, operation/emergency stop, etc. are displayed and operated on the control panel of the electrical cabinet. The equipment can achieve automatic variable speed operation in different time periods |

|

Vacuum System |

Equipped with vacuum buffer tank and switch; Standard vacuum pump 2XZ-2, with a power of approximately 0.37KW |

|

Vacuum Degree |

-0.098Mpa |

|

Lifting System |

turbine worm, electric lifting |

|

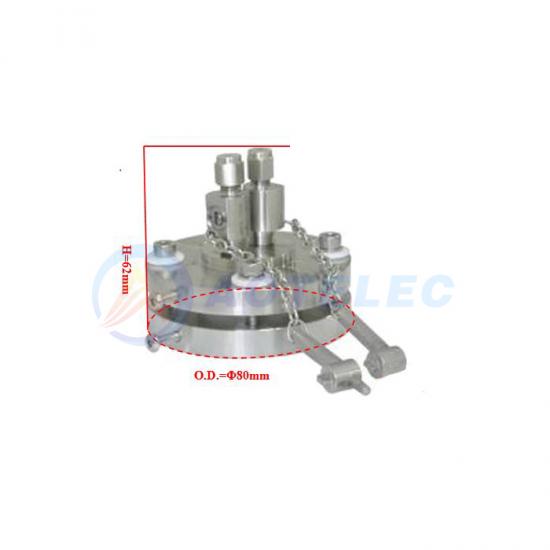

Positioning System |

Equipped with positioning adjustment device. The barrel body and lid are precisely matched with the positioning stopper, ensuring accurate positioning and vacuum sealing |

|

Insulation Layer

|

Cooling water for cooling, no need for insulation |

|

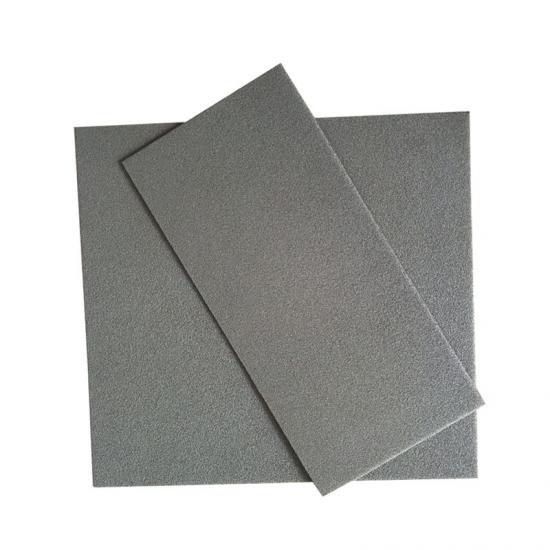

Applicable Slurry |

Production of various slurries and other materials with a kinematic viscosity of 1000-100000cp |

|

Equipment Size |

L1150 * W960 * H2050mm (subject to actual size) m |

|

Weight |

550Kg |

|

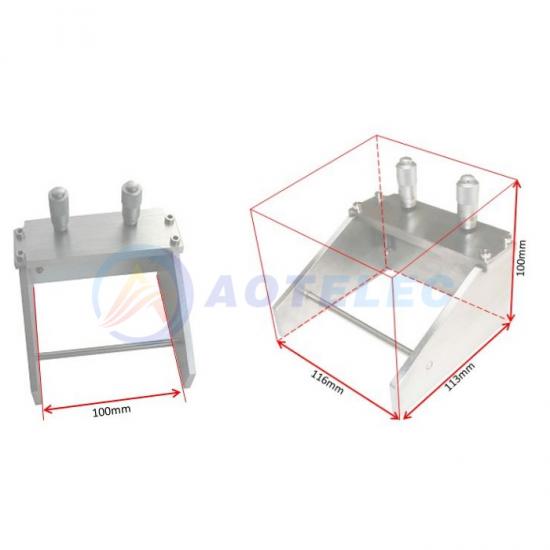

Mixing Tank |

Upper bucket components Upper bucket material SUS304 Powder feeding port Quick opening interface DN50 Spotlight port DN50 View window DN50 Vacuum port G1/2 ", ball valve Exhaust port G1/2 ", ball valve Lower bucket components Design total volume 8L Effective volume 5L Container inner diameter 240mm Depth inside container 180mm Container material and material contact part SUS304 Temperature regulating jacket in the form of a single-layer jacket on the barrel wall, used for cooling or heating; Single layer jacket at the bottom of the bucket, used for cooling or heating Temperature regulating jacket interface G1/2 ", equipped with quick opening flexible joint, jacket pressure resistance ≤ 0.4Mpa, inlet/outlet, one each Discharge form: A 3/4 "discharge ball valve at the bottom of the bucket Design ambient temperature range of 0 to+55 ° C |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported