-

Jan , 12 2024

There are various types of lithium-ion batteries, and different types of batteries are differentiated by the use of different cathode materials. In this article, I will describe the advantages, disadvantages and applications of lithium manganate cathode materials, as well as the main preparation methods. What is Lithium Manganate? Lithium manganate, with the chemical formula LiMn2O4, has a cubic s...

View More

-

Jan , 25 2024

The electrodes of lithium-ion batteries are mainly composed of active substances. binders, conductive agents, and current collectors. Although the content of binders and conductive agents is very low, they are crucial for the performance of lithium-ion batteries. The main function of the binder is to bond solid particles such as active substances and conductive agents into a wh...

View More

-

Apr , 25 2024

With the rapid development of technology, the application of lithium batteries in the energy field is becoming increasingly widespread. From smartphones and electric vehicles to large-scale energy storage systems, their efficient and environmentally friendly characteristics have been widely recognized. The lithium battery coating machine, as a key equipment in the lithium battery manufacturing pro...

View More

-

May , 17 2024

May , 17 2024

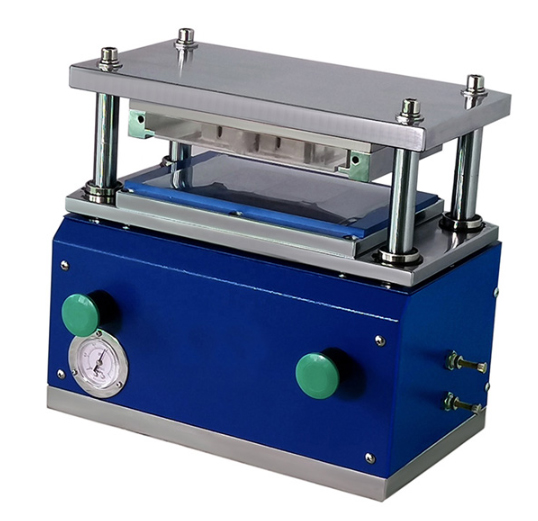

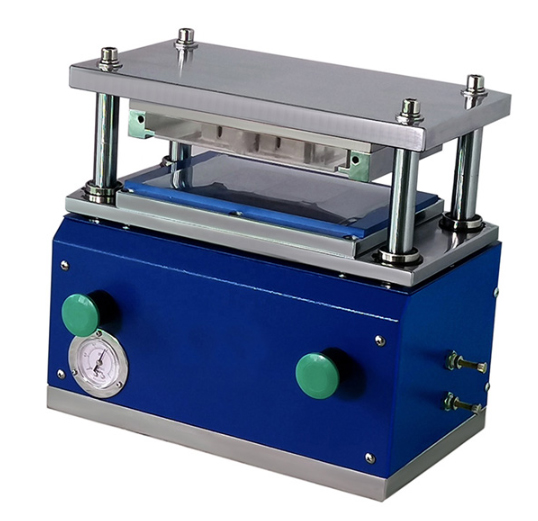

1. Introduction 2. Types and configurations of battery roller machines 3. Operation steps of battery roller machine 4. Safety precautions 5. Application range 1. Introduction In the battery manufacturing industry, batteries play a crucial role in rolling machines. It is mainly used for rolling, compressing, and shaping battery electrodes to ensure uniform distribution ...

View More

-

May , 30 2024

May , 30 2024

1. Introduction 2. Overview of battery coating machine 3.Design and Manufacturing of Battery Coating Machine 4.Application and advantages of battery coating machine 5.Development Trends and Future Prospects 1、 Introduction The battery coating machine plays a crucial role in the battery manufacturing process, and its importance and role are mainly reflected in the following aspects: (1)Improving ba...

View More

-

Jul , 04 2024

Jul , 04 2024

I. Introduction II. Functions of Cylindrical Battery Grooving Machine III. Operating Principles of Cylindrical Battery Grooving Machine IV. Applications of Cylindrical Battery Grooving Machine V. Conclusion I. Introduction Brief overview of cylindrical battery technology and its significance in modern energy storage systems. Introduction to the cylindrical battery grooving machine and ...

View More

-

Jul , 11 2024

Introduction Lithium-ion batteries (LIBs) have revolutionized the energy storage landscape, powering everything from portable electronics to electric vehicles and large-scale energy storage systems. At the heart of these batteries lie the cathode materials, which play a pivotal role in determining their performance, safety, and cost-effectiveness. This article delves into the intricacies of LIB ca...

View More

-

Jul , 18 2024

Jul , 18 2024

The battery coating process involves several critical steps utilizing specialized equipment to ensure the proper application and adhesion of coating materials onto battery surfaces. The following is an outline of the process with key steps highlighted: I. Introduction Battery coating equipment is a vital component in the battery manufacturing process, particularly for lithium-io...

View More

-

Jul , 25 2024

Jul , 25 2024

Introduction: The pouch cell battery electrode punching machine plays a crucial role in the production process of pouch cell batteries, particularly in the preparation of electrodes. Its primary function is to precisely punch out electrode materials such as battery cathodes, anodes, and separator sheets into standardized samples or strips, ensuring uniformity and precision for subsequent battery a...

View More

-

Aug , 01 2024

Capacity is the primary attribute of a battery, and insufficient cell capacity is also a common problem encountered during sample and mass production. This article mainly analyzes the problem of no capacity in battery cells. What is the reason for insufficient battery capacity? When hearing that the battery cell capacity is insufficient, the first reaction should be to confirm whether there i...

View More

-

Aug , 08 2024

The lithium battery drying oven, also known as a vacuum drying chamber, plays a crucial role in the manufacturing process of lithium batteries. Its primary application lies in the drying and baking of battery components, particularly the battery electrodes, to enhance the overall quality and performance of the final product. Below is a detailed account of its applications: 1. Drying an...

View More

-

Aug , 15 2024

Button battery assembly is a meticulous process that requires specific materials, follows a precise sequence of steps, and employs specialized preparation methods. Below is a comprehensive overview in English. Materials Required Positive Electrode Materials: Typically, the positive electrode (cathode) consists of active materials like lithium cobalt oxide (LiCoO2) or lithium iron ...

View More

May , 17 2024

May , 17 2024

May , 30 2024

May , 30 2024

Jul , 04 2024

Jul , 04 2024

Jul , 18 2024

Jul , 18 2024

Jul , 25 2024

Jul , 25 2024