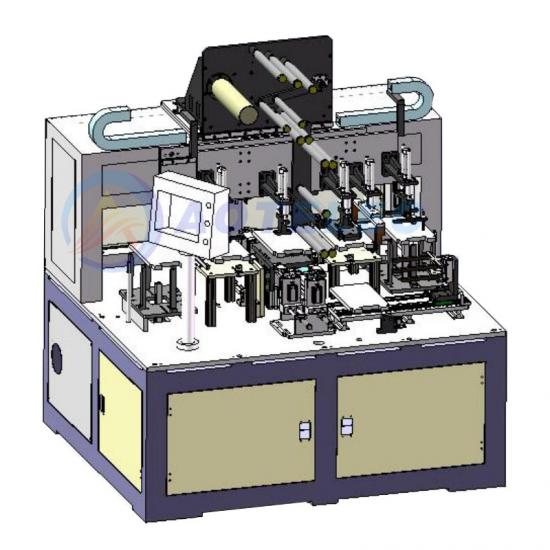

Desk-Top Precision Spot Welder Machine for Battery Tab Welding

Introduction:

ThisAOT-PS250 Spot welding machine mainly used for 18650 battery pack tab welding, itis suitable for nickelstrip/foil thickness from 0.05-0.25mm.(pure nickel strip better thinner than 0.2mm)

Features:

1. Dual pulse welding: the first pulse is used to the workpiece surface coating and oxide removal, and make the contact place in welding electrode produce slight deformation, improve the effective contact area, the second pulse is used to ontology metal welding, can effectively promote the quality of welding and reducing welding spatter.

2. Control model: CPU control, precision pulse energy Adjustable(0-99.9%), preloading time and the holding time Adjustable(0-2.55s)

3. Multiple fault protection: equipped with two sets of different kinds of protection circuit, in order to prevent the equipment from overheating, outside pressure and power fluctuations butt welding machine interference, in order to protect the welder in harsh environment.

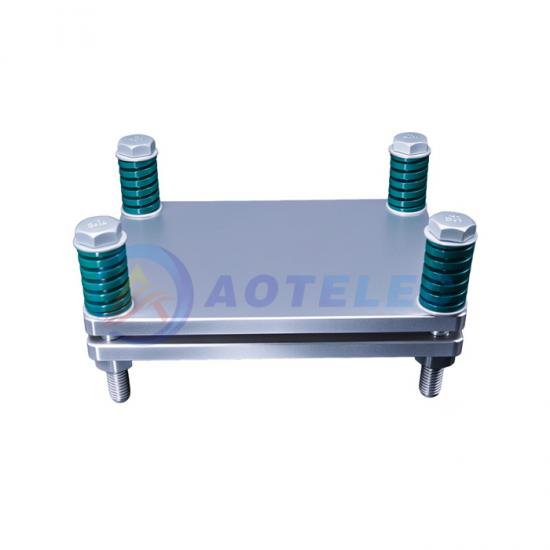

4. Precision welding head design: adopt cylinder combined with spring buffer, make the two welding needle can adjust pressure when welding; Inside of machine head adopts photoelectric pressure switch, to protect the reliability of the welding.

5. Unique structure: the workbench stepless lift, convenient to precision adjust the position; unibody design, pneumatic operation, easy operating

Specifications:

|

Model |

Cylindrical Battery Spot Welding Machine AOT-PS250 |

|

Power |

15KVA |

|

secondary side of welding current |

3000A |

|

Secondary no-load voltage |

5.5V |

|

Input |

220V AC / 50Hz |

|

Working pressure |

0.5-0.8Mpa |

|

Welding pulse |

Single pulse, double pulse, multiple pulse programmable |

|

Welding control model |

Foot switch control |

|

Net Weight |

About 30KG |

|

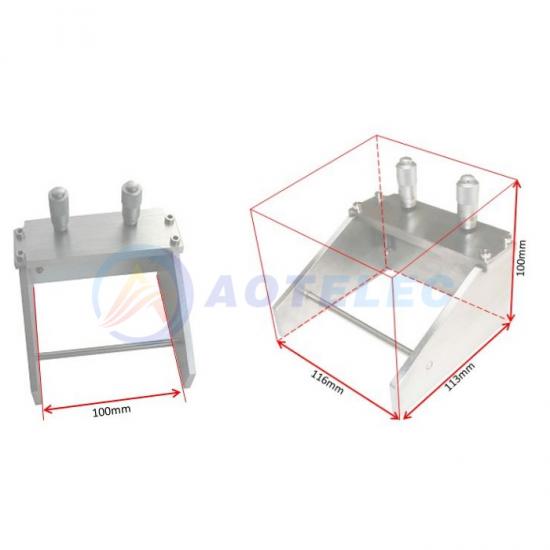

Dimension (L*W*H) |

400mm*220mm*360mm |

Exhibition

Certificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported