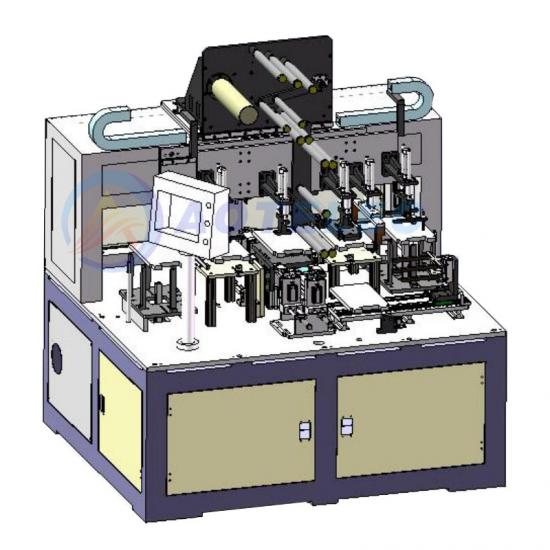

Lab Tape Casting Coater with Vacuum Chuck

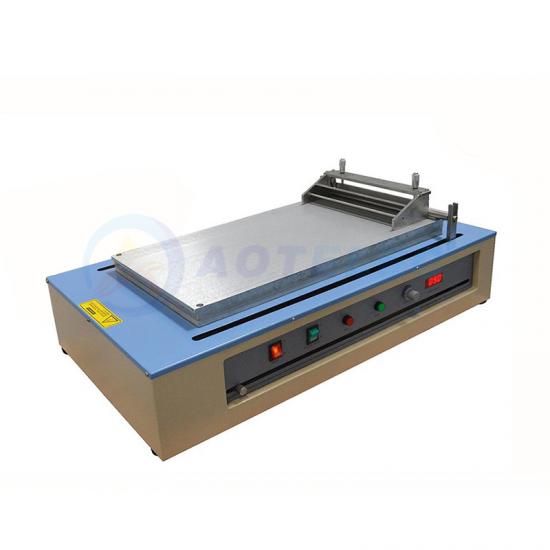

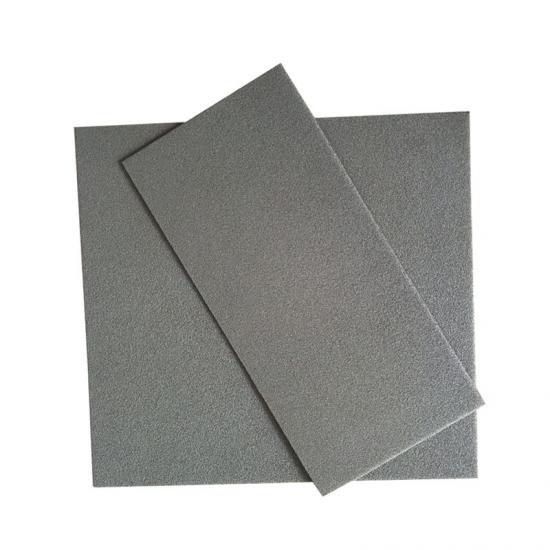

This tape casting machine is dedicated to the continuous coating process of cathode and anode electrode of lithium ion batteries, suitable for small-scale experiments in colleges and enterprises.

It can also be used for ceramic films, crystal films, special nano films, etc.

The body is made of stainless steel, which is beautiful, durable, and the surface is sprayed with plastic, which is easy to operate.

Features:

1. The film coating motor is a low-speed synchronous synchronous motor from Taiwan Edley;

2. The ball screw and linear guide are only imported from Taiwan with high-precision HIWIN brand:

3. The doctor blade(applicator) adopts the SUS316L stainless steel material imported from Finland:

4. Drying system with strong wind heating and digital display temperature control, the maximum working temperature is 150℃;

5. The coating film speed can be adjusted within the range of 0-100mm / sec, with digital display;

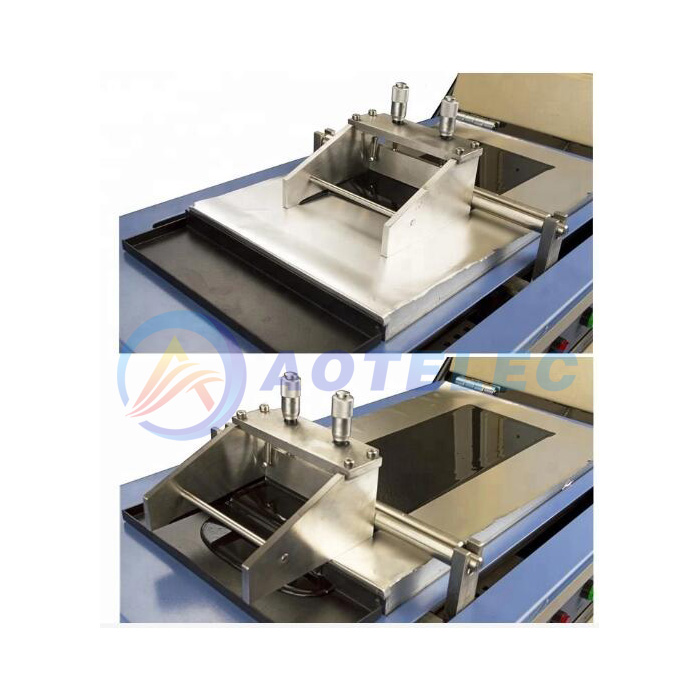

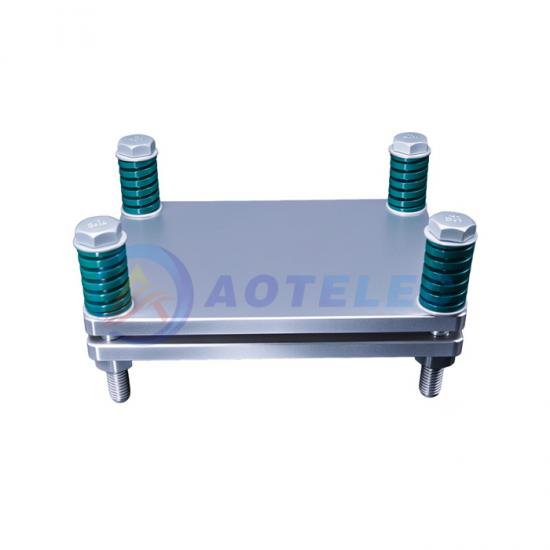

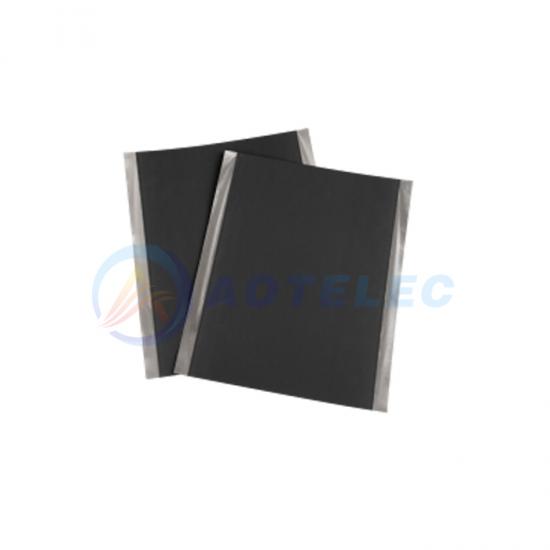

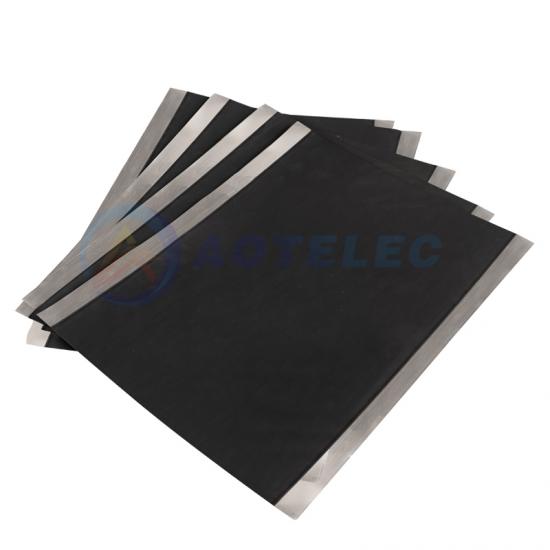

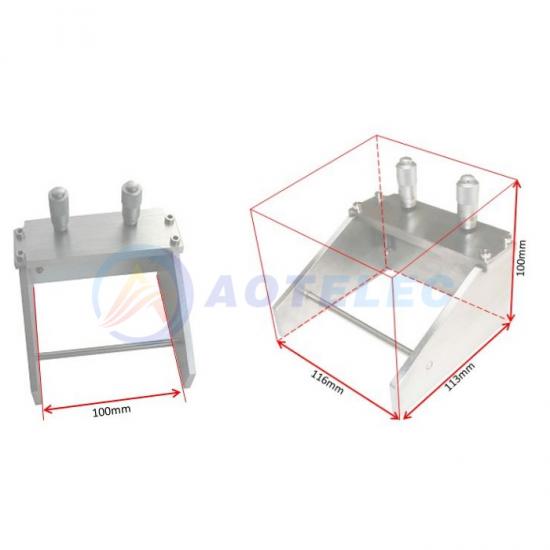

6. Vacuum aluminum plate, can quickly place or remove the electrodes, copper foil, aluminum foil;

7. Doctor blade with adjustable coating thickness (accuracy 0.02mm) width 0-150mm;

Specification

|

Item Name |

Automatic Tape Casting Coater Machine with Heater and Dryer |

|

Model |

AOT-TCM-350 |

|

Source Voltage |

AC220V ±10%, 50Hz |

|

Power |

650W |

|

Stroke Range |

10 - 350mm adjustable by using Adjustable Position Switch |

|

Vacuum plate |

Equipped with vacuum aluminum plate |

|

Coating Speed |

0-100mm/s, Step-less transmission ;Accuracy: 10mm/sec |

|

Dimension of vacuum plate |

L465mm×W200mm×H30mm |

|

Doctor Blade width |

150mm |

|

Regulating range of blade |

0.02~2.5mm |

|

Heating temperature |

Room temperature ~ 150℃ Digital displayed thermostat, the accuracy is±1℃ |

|

Weight |

65KG |

|

Dimension |

AboutL700mm×W310mm×H330mm |

|

Standard Configurations |

*applicator *no-oil vacuum pump * Pump pipe *horizontal rod |

Exhibition

Cerificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported