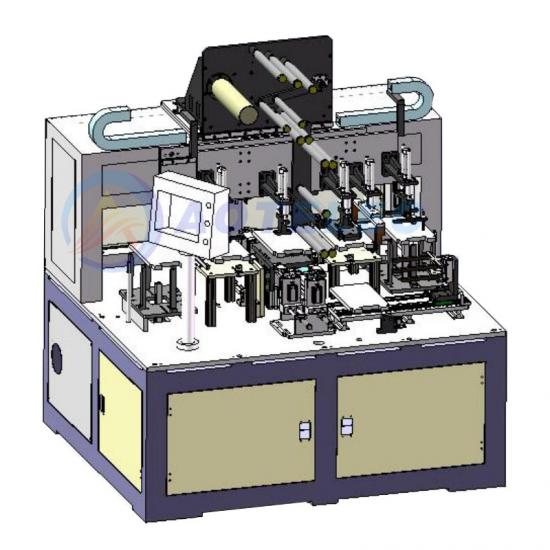

Dual Work Station Vacuum Glove Box for Lab Polymer Battery

Brief Introduction

Double station, single-sided operation, integrated with single-column purification unit, PLC control and touch screen operation, vacuum pump, bracket, a closed cabinet with tilting operating surface and detachable safety glass front window. Under standard conditions , that is, 20 degree centigrade constant temperature, a standard atmospheric pressure, 99.999% inert gas source, water and oxygen index is less than 1 ppm.

Technology parameters

| product model |

AOT-VGB-4 |

|

|

Glove box |

Box |

Box inner size: (L*W*H)=2440×750×900mm Box material: stainless steel 304, thickness 3mm Inner surface: stainless steel wire drawing treatment Outside surface: paint, white |

|

Front window |

Tilt windows, transparent tempered safety glass, thickness 8 mm |

|

|

Glove ports |

The material is polyoxymethylene, O-ring seal, self-lubricating performance, easy to maintain, and good sealing performance |

|

|

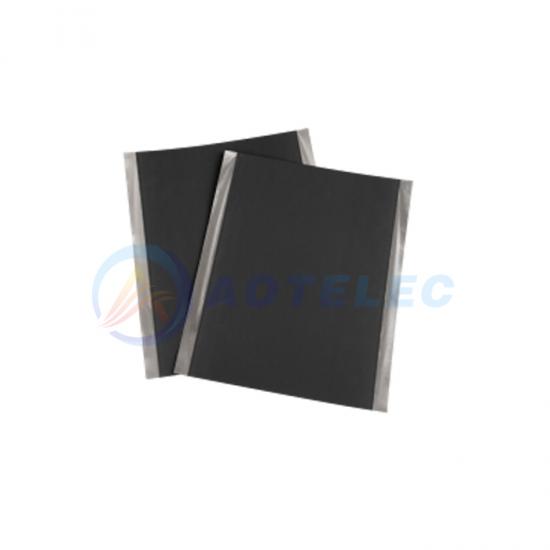

Gloves |

Butyl rubber, diameter 8", length 32" |

|

|

Filter: |

0.3 microns, a gas inlet and a gas outlet |

|

|

Shelf |

Stainless steel, 2 layers |

|

|

Lighting |

LED lights, installed in front of each glass window |

|

|

Connector |

Standby interface7pcs, DN 40 KF, Power interface 1pc (220V) |

|

|

Bigger transitive cabin |

Chamber |

Size: diameter 360mm, length 600mm Material: 304 stainless steel Surface: inner surfacewire drawing process, outer surface painting (white) |

|

Accessary |

Sliding tray: 304 stainless steel Door: double door, anodized aluminum material, thickness 10mm, vertical operation, with lifting mechanism Pressure gauge: Analog display |

|

|

Control |

Solenoid valve touch screen automatic operation |

|

|

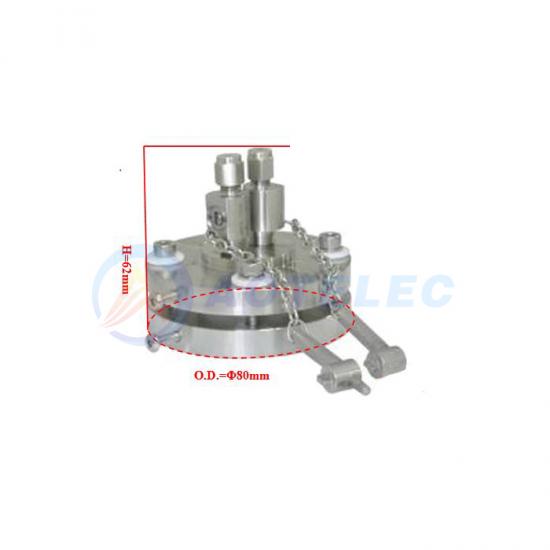

Smaller transitive cabin |

Chamber |

Size: diameter 150mm, length 300mm (100mm lengthinto the glove box) Material: 304 stainless steel Surface: inner: wire drawing process, outer: painting (white) |

|

Accessary |

Door: double door, button press Pressure gauge: analog display Small compartment tray: 304 stainless steel |

|

|

Control |

Manual valve manual operation |

|

|

Gas purification circulation system |

Purification column |

Function: gassealed, remove water, remove oxygen Container material: 304 stainless steel Purification materials: copper catalyst: 5kg, molecular sieve: 5 kg Purification capacity: oxygen: 60L, water: 2Kg Water and oxygen indicators: less than 1ppm |

|

Circulatory system |

Working gas: nitrogen, argon Recycling capacity: integrated fan flow 90m³ / h, install frequency conversion |

|

|

Regeneration |

Operation: PLC automatically controls the regeneration process Regeneration gas: working gas mixed with hydrogen gas, (hydrogen 5-10%) |

|

|

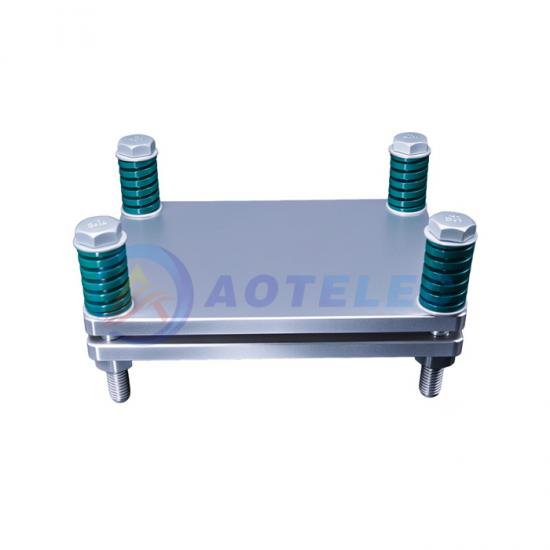

Vacuum pump |

8m³ / h, rotary vane pump, with oil mist filter, air vibration control |

|

|

Valves |

Main valve: DN 40 KF, electrically operated angle valve Control valve:electromagnetic integrated valve (stainless steel integrated valvebase, single column for the six valve integration) |

|

|

Control System |

Function |

Including self-diagnosis, power-off self-starting characteristics, with pressure control and adaptive function Automatic control, cycle control, password protection, unit control using Siemens PLC touch screen |

|

Pressure control |

Control box, transition chamber pressure,the working pressure of the cabinet can be set freely within +/- 10mbar, and the system automatically protects beyond +/- 12mbar. |

|

|

Pedal |

Control the box pressure, easy to operate boost and buck |

|

|

Display system |

Using Siemens PLC touch screen, display running status, box pressure, system records etc |

|

|

Vacuum system control |

Vacuum pump, can be manually or through the PLC to start, flow 8m³/h,vacuum of the transitionchamber, and keep the box pressure balance, vacuum pump limit vacuum ≤ 2x10-1pa |

|

Exhibition

Certificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported