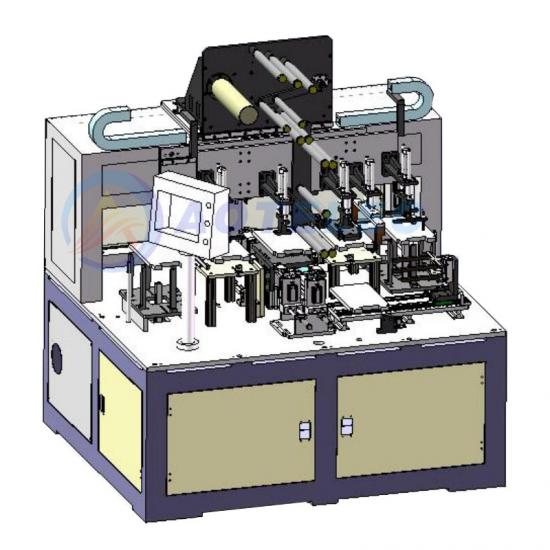

Product introduction

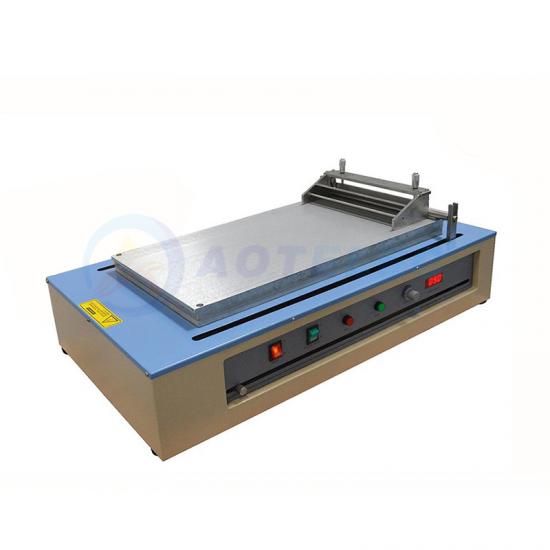

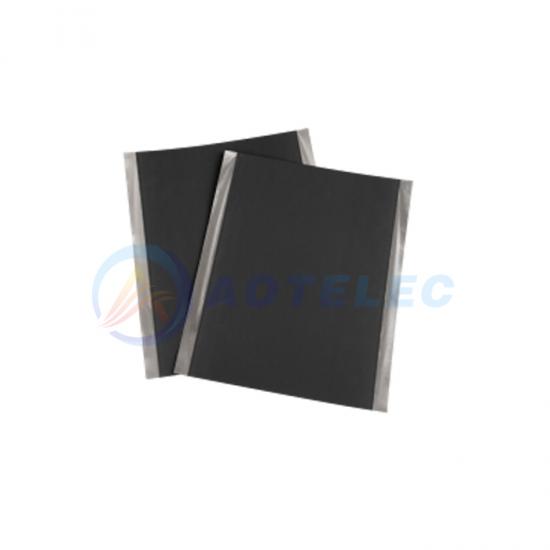

The manual roller machine is mainly suitable for manual rolling of battery materials in the laboratory, a small amount of precious metal materials such as gold and silver, and non-ferrous materials such as copper and aluminum. It is especially suitable for thinning and increasing density of lithium battery plates for clean energy materials. The machine adopts gear transmission to achieve the pressing of the roller, the thickness of the rolling can be adjusted, and the utility model is convenient to use.

Technical Parameters

|

Model |

Manual Roller Press AOT-SG-100H |

|

Roller diameter |

100mm |

|

Roller surface hardness: |

HRC62 or more |

|

Tablet thickness |

0~3mm |

|

Tablet width |

0~100mm |

|

Roll placement |

Horizontal placement |

|

Net weight |

60KG |

|

Warranty |

2 years |

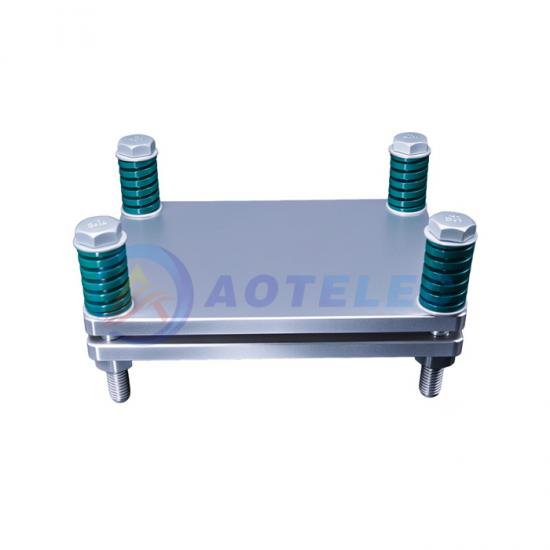

Tablet thickness adjustment method

1. Use the Allen key to loosen the fastening screws between the left and right support and the slider (8 on the left and right sides);

2. Use an open-end wrench to loosen the adjustment nuts on the left and right sides;

3. Rotate the small handles on the left and right sides to the appropriate position. Use the plug gauge (configured in the box) to check the gap size and whether it is uniform. The small handles on both sides should be balanced to avoid damage to other parts;

4. Tighten the fastening screws between the left and right side supports and the slider with an Allen key (configured in the package);

5. Use an open-end wrench to tighten the adjusting nuts on the left and right sides and check the clearance;

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported