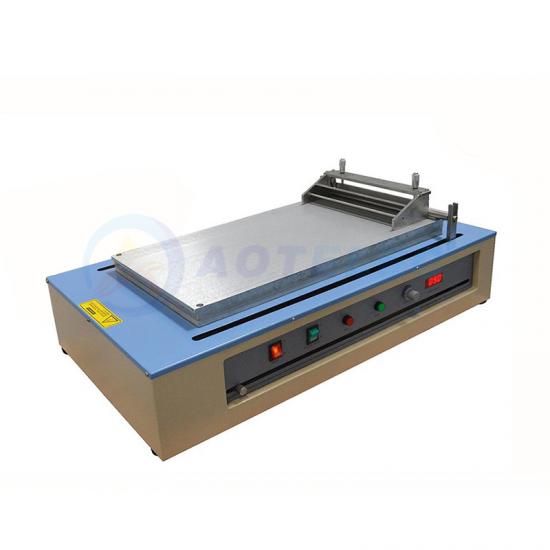

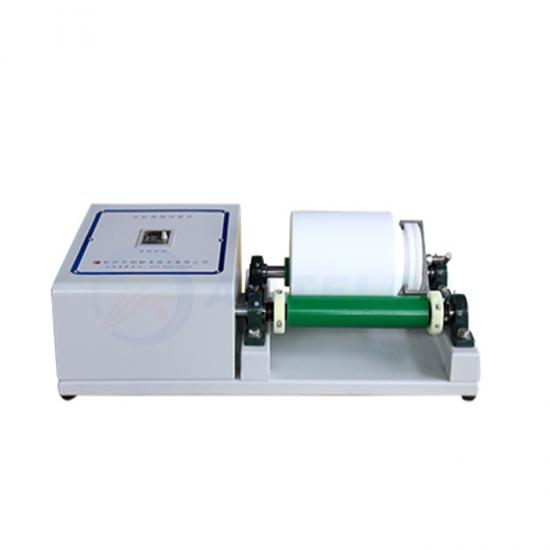

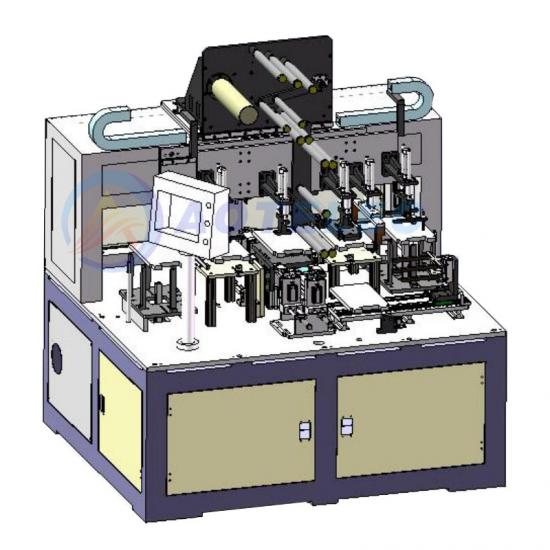

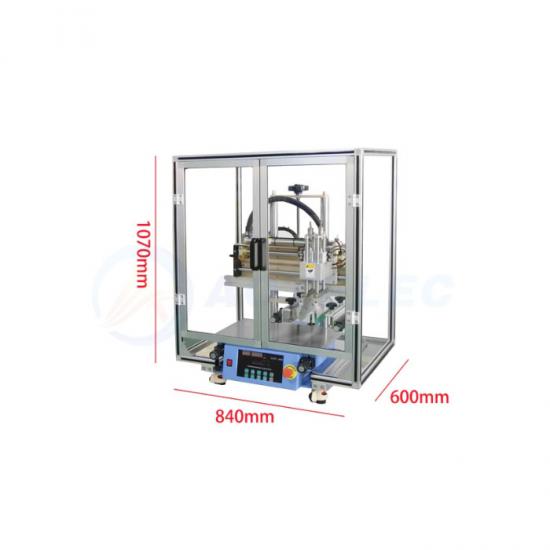

Battery Casting Coater Machine with Heated Vacuum Bed And Doctor Blade

MSK-AFA-H200A Is an standard Compact Tape Casting Coater with a vacuum chuck hotplate up to 250ºC and an active carbon filter on the top cover to protect the lab environment.

SPECIFICATIONS:

|

Power |

· 208 - 240V AC 50/60Hz · 1500W |

|

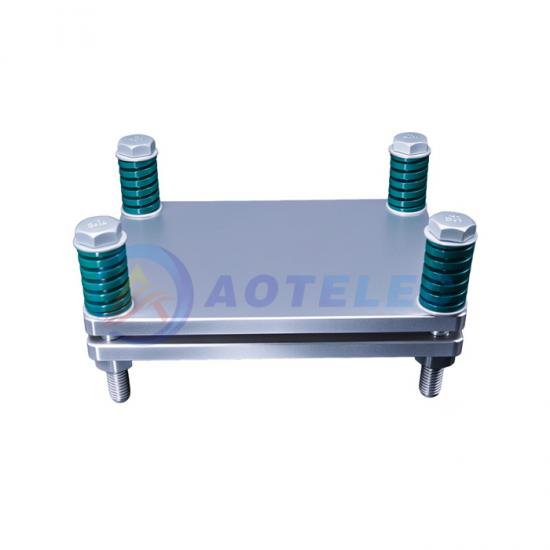

Heatable Vacuum Platform |

· Vacuum chuck made of aluminum alloy with the micro-size holes · Vacuum chuck Area: 400mm (L) x 250mm (W) (16"L x 10"W ) · Heating elements are installed inside the chuck which can reach 250ºC Max. · Precision digital temperature controller with +/- 1ºC accuracy |

|

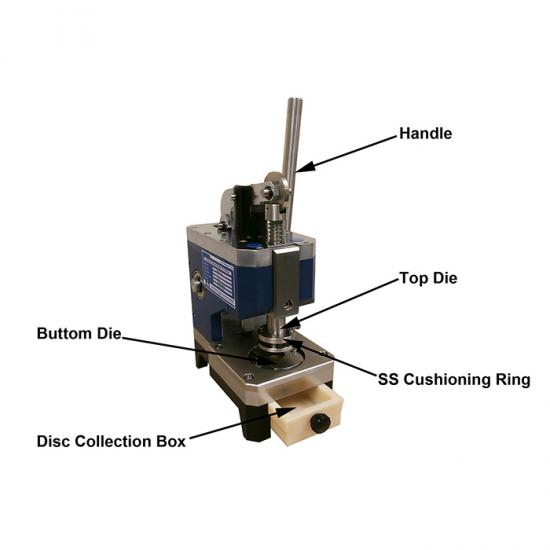

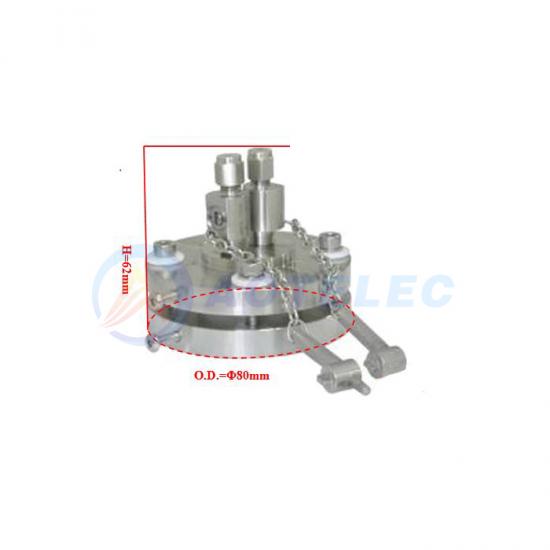

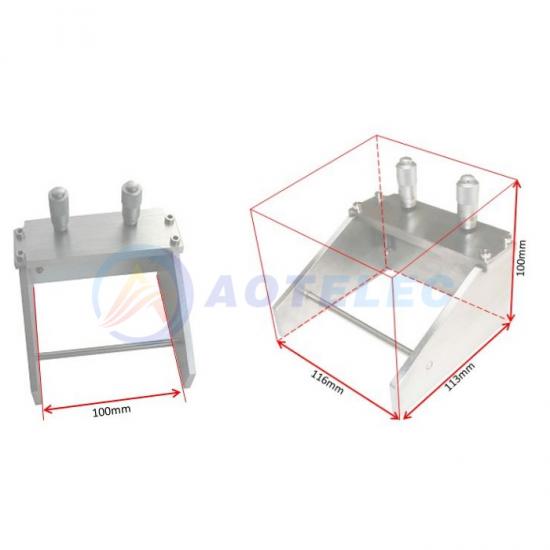

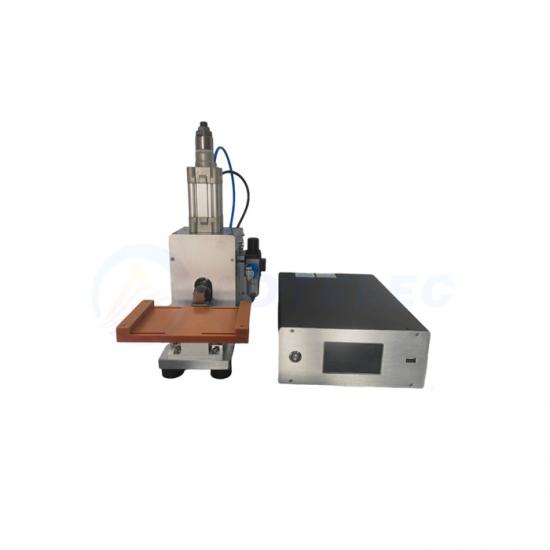

Film Applicator |

· Built-in pushing bar for using micrometer adjustable applicator · 180 mm width Applicator with micrometer adjustable head is included for immediate use (Click picture 1 to see details) · 24VDC motor driving mechanism, which can be used under Ar gas glovebox. |

|

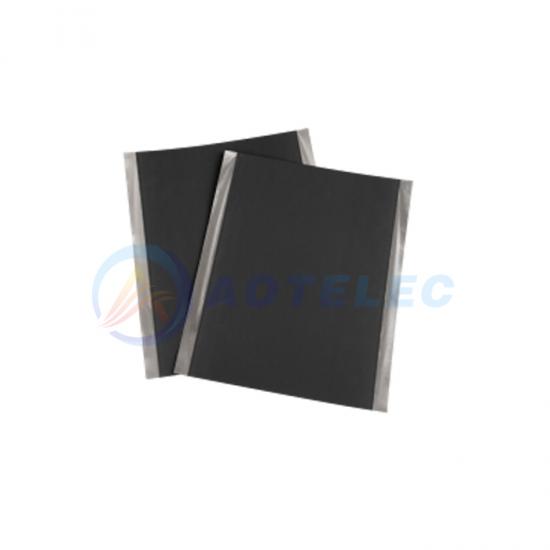

Coating Area |

· Standard Package: 350mm(L) x 180mm(W) due to the width and occupied area of the 180 mm applicator. · Maximum: 350mm(L) x 230mm(W) Reduced width to avoid slurry spilling off the vacuum bed. · Length 10 - 350 mm adjustable by using Adjustable Position Switch

|

|

Accuracy of Film thickness |

· +/- 0.01mm |

|

Traverse Speed & Distance |

· Travel Speed: 0 - 80mm/sec variable · Travel distance: 0 - 400 mm adjustable |

|

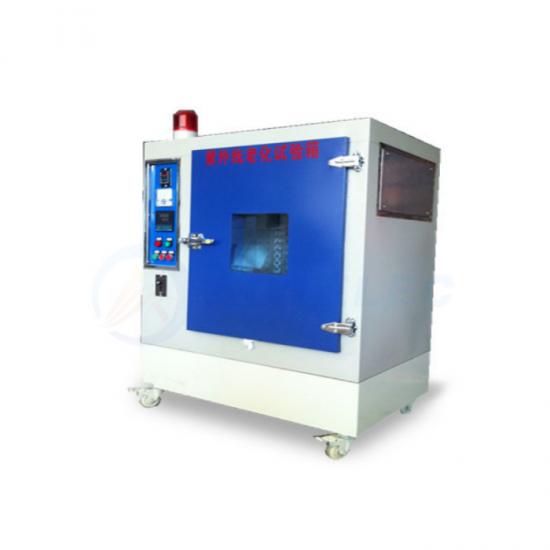

Top Cover and Filter |

· Active carbon filter and venting fan are installed on the top cover · The filter will remove organic vapor to make the lab environment safe & clean |

|

Net weight |

40kg |

Exhibition

Cerificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported