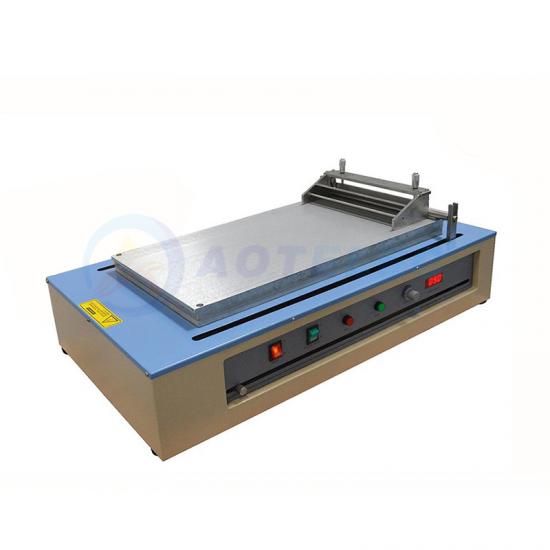

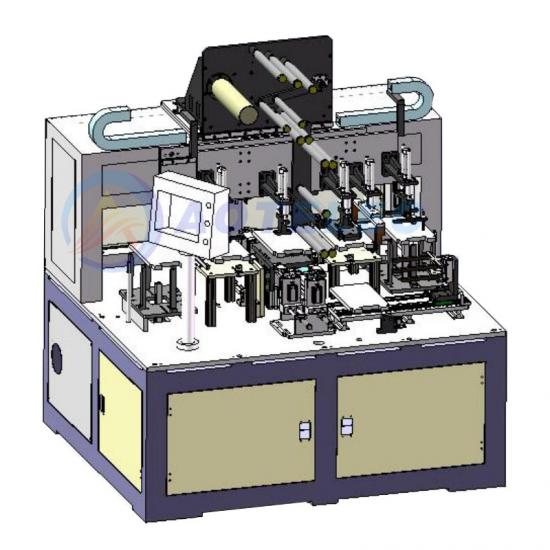

AOT-MSK-AFA-II-VC is a Large Automatic Film Coater with Vacuum chuck designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when coating on the thin substrate and making uniform tape casting. This machine can be used for research on ceramic tape casting and Li-Ion battery electrode coating.

SPECIFICATIONS

|

Working Voltage |

INPUT: 24VDC One UL/CSA listed 100-240VAC IN - 24VDC OUT power adapter is included. |

|

Max. Power Consumption |

100W |

|

Traverse Speed |

5 - 100 mm/sec variable Accuracy: 10mm/sec

|

|

Stroke Length |

10 - 550 mm adjustable by using Adjustable Position Switch |

|

Max. Coating Dimensions |

250mm(W) x 550mm(L) |

|

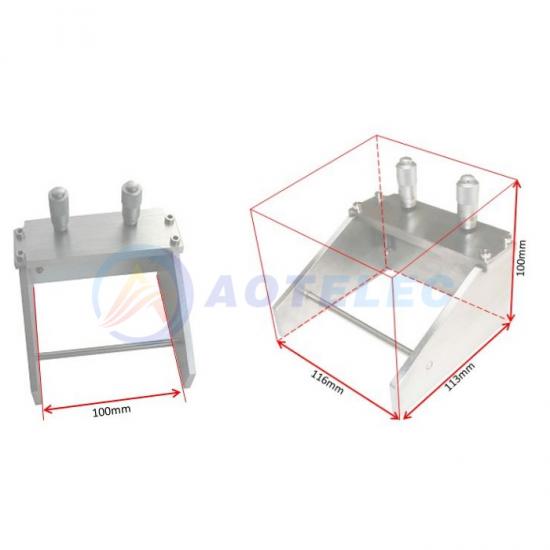

Vacuum chuck |

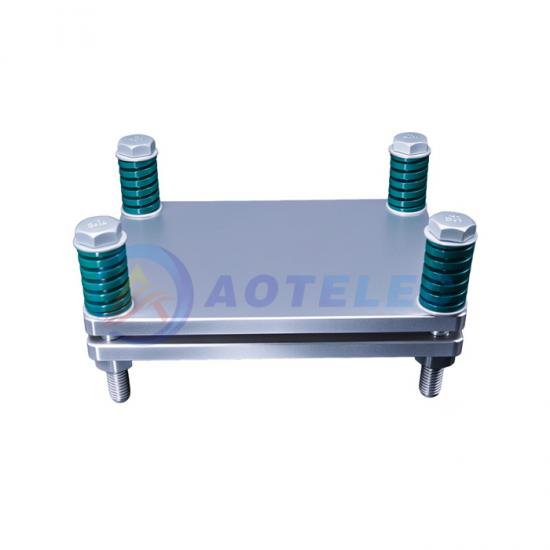

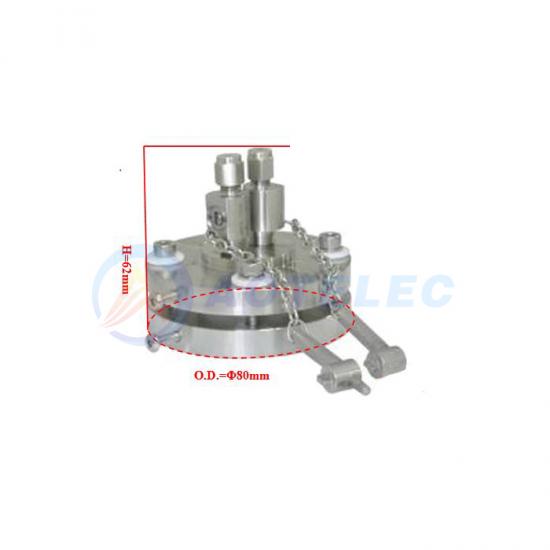

Vacuum chuck made of Aluminum alloy with < 1 mm holes Vacuum Chuck Dimensions: 600mm(L) x 300mm(W) x 20mm(H)

|

|

Film Applicator |

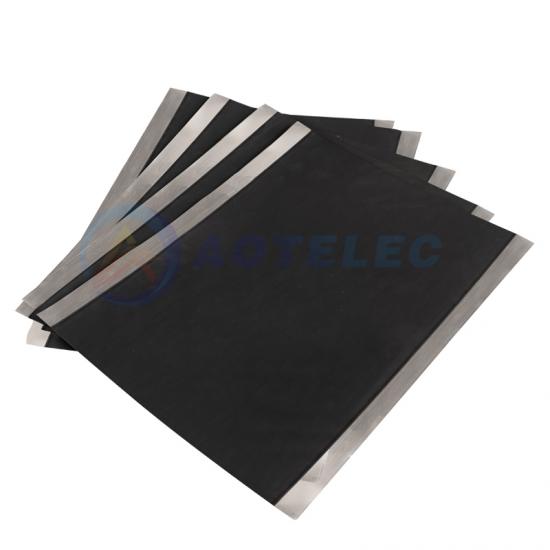

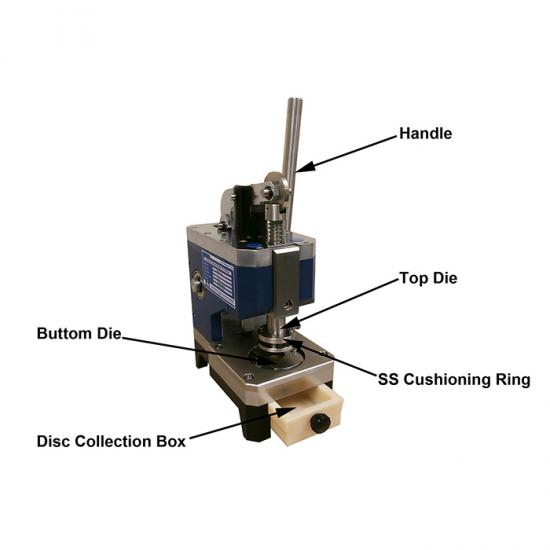

1. 250 mm width Micrometer Adjustable Film Applicator is included, with adjustable thickness from 0.01 - 5 mm 2. Traverse Pusher is included for pushing the doctor blade to ensure constant speed coating 3. Note: Thinnest film can be achieved is > 10 micron |

|

Product Dimensions |

805mm(L) x 430mm(W) x 223mm(H) |

|

Compliance |

CE certified |

|

Net Weight |

30 kg (67 lbs) |

|

Shipping Dimensions |

48"(L) x 40"(W) x 37"(H) |

|

Shipping Weight |

255 lbs |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported