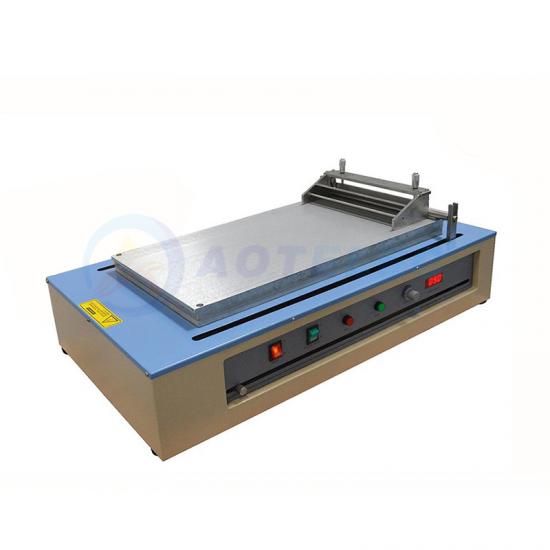

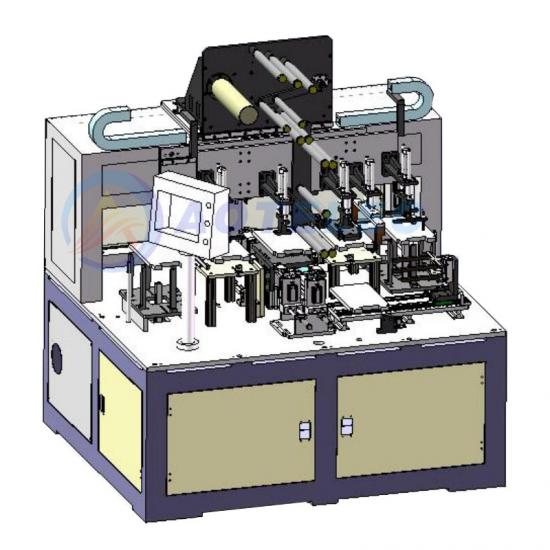

1、Equipment Overview

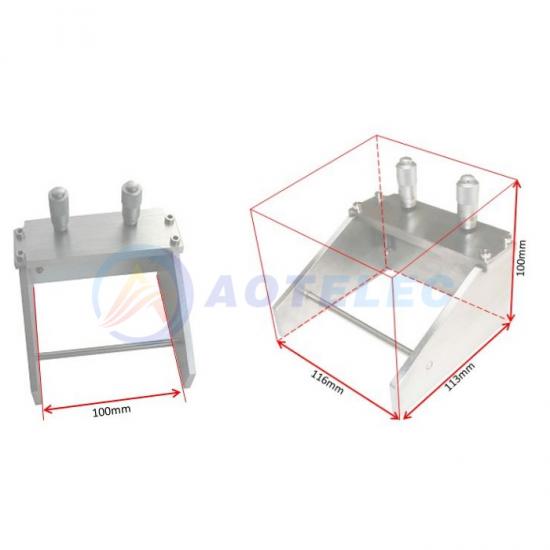

This equipment is mainly used for experimental square lithium-ion power battery cell Z-shaped stacking, the equipment adopts automatic tension control system, cylinder driven diaphragm reciprocating movement, manual pressure knife to assist stacking, with high stacking efficiency, neatness and good characteristics.

2、Work flow

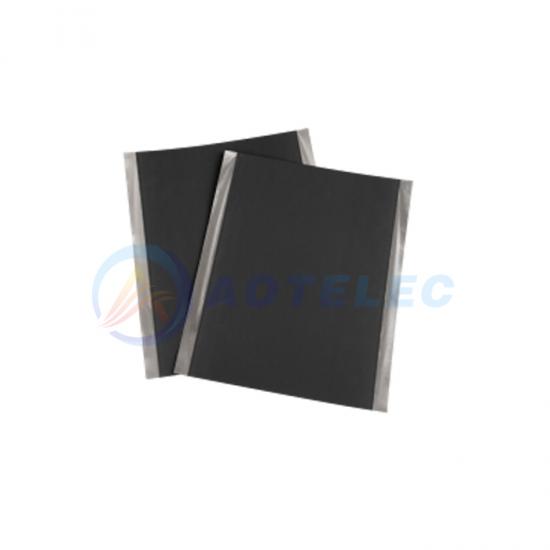

The separate is actively unwound and introduced into the stacking table with positioning fixture through the tensioning mechanism; the cylinder drives the diaphragm to reciprocate and carry out Z-shaped stacking; the pole piece is placed manually and the pressure knife is operated manually to assist in stacking; after the stacking is completed, the core is transferred through the special fixture and then manually wrapped up and glued;

The process flow diagram is as follows:

Technical parameters

Item

Acceptance process technical parameters

Single laminated time

3.0-5.0S(depending on proficiency)

Polar plate and diaphragm adjacent precision

Center deviation ±0.5mm

Diaphragm face alignment accuracy

±0.5mm

Alignment accuracy of adjacent pole pieces

±0.5mm

Overall alignment accuracy of the pole slice

±0.5mm

Number of layers

It can be set within the thickness adaptation range

Utilization rate

99.5%(fault caused only by the machine)

Pass rate

99%(only caused by the machine)

Overall dimension

Length 550 * Width 850 * Height 600mm

Power source

Voltage: AC220V±10%; Single-phase;

Power: 200W; Frequency: 50Hz

Compressed air

Pressure: 0.4~0.7MPa(5kgf~7kgf/cm²);

Air \ dust

Free of salt gas, toxic and corrosive gas; There should be no conductive dust

Magnetic boundary and vibration

The magnetic boundary of the device should not be affected; There should be no shock and obvious vibration

Certificate

Cooperative brand

Exhibition

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported