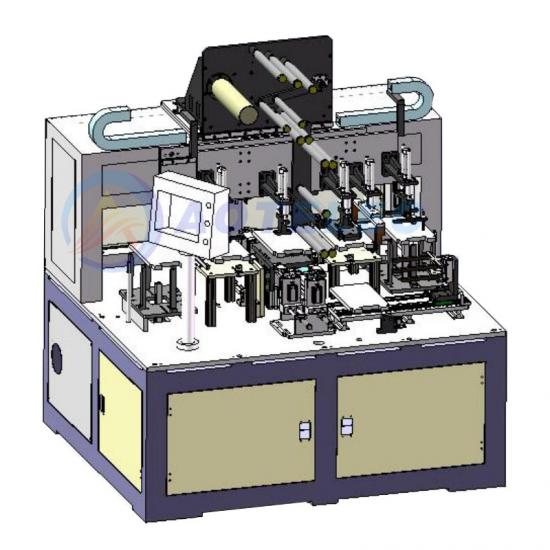

Insulation Pasting Equipment Barley Paper Sticking Machine for 18650 Battery

Features:

1.Using hopper loading box, it is available for 450-500PCS battery cells (for continue working about 10 minutes) , also can be gradually added cells manually.

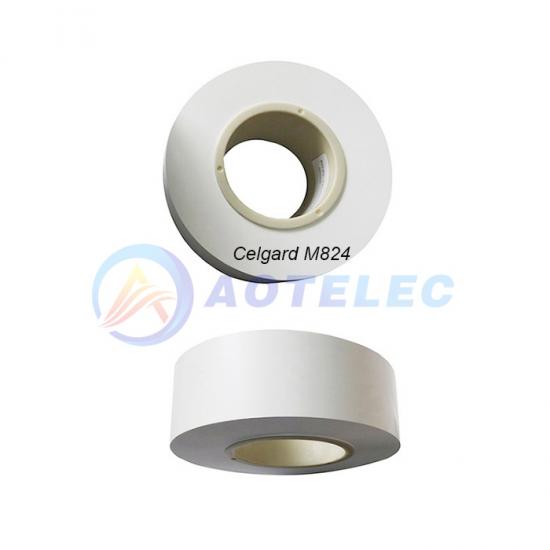

2.The insulating highland barley paper uses the roll material, reduces the waste, saves the cost.

3.The double manipulator takes and puts the battery, guarantees the battery to transfer freely from the channel normally.

4.Equipment debugging is simple, easy to learn, fixed parameters, with manual operation and one-step operation and automatic operation procedures.

5.Equipment with fault alarm, according to the prompt to clear the fault

|

Insulation Paper Sticking Machine for 18650 |

|

|

Power |

AC220V±10% 1.6KW 50HZ±10% |

|

Range of application |

Battery cell positiveand negative insulating barley paper |

|

Barley/Insulation paper thickness |

0.1 mml-0.3 mm |

|

Punching Pad Power |

0.4 kw variable frequency motor debugging |

|

Control Devices |

7.5-inch touch screen, 2-axis stepper motor design, 42-point PLC programmer |

|

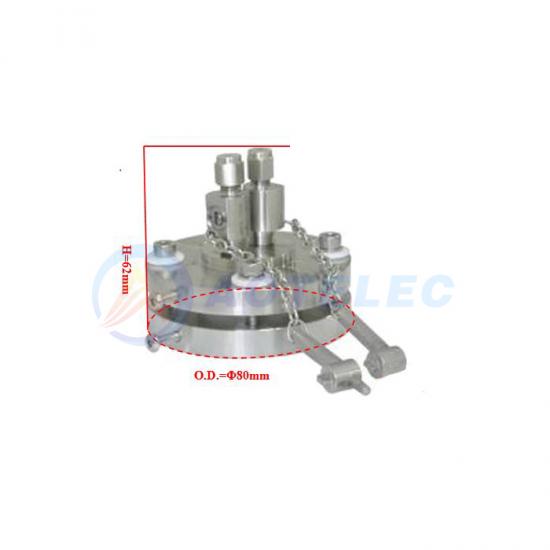

Air pressure |

0.4-0.8Mpa |

|

Production Efficiency |

About4500pcs/hour |

|

Barcode Reader |

Optional |

|

Production Efficiency with barcode reader |

About 3000pcs/hour |

It can be connected to automatic sorting machine with seamless joint

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported