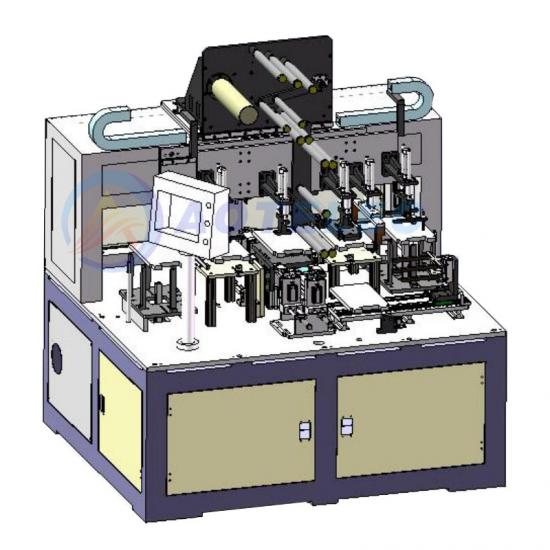

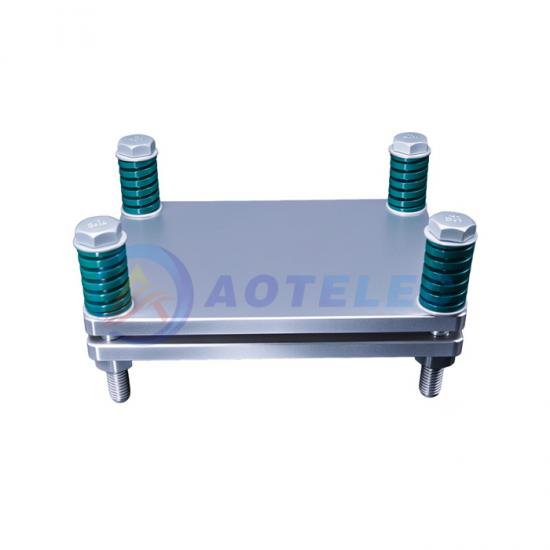

Automatic Double Sides Spot Welding Machine For Cylindrical Battery

Applicable to electric vehicle battery pack, street lamp battery pack, automobile battery module, balance vehicle battery pack, scooter battery pack, mobile power supply, starting battery pack module, power tool battery pack, notebook battery pack, various electronic products and other battery combinations!

Main features:

1. Support break point startup, automatic startup and manual startup mode conversion.

2. Simple programming, support any point programming and array programming, realize skip spot welding, fast switching between single point and double point modes, optimize spot welding path, improve efficiency, save 99 groups of programming files on local disk, and import graphics through USB interface.

3. It can be divided into super operator, maintenance, administrator, etc.

4. Inverter DC welding power supply is adopted, which has stable performance, fast welding speed and constant current working mode, so as to eliminate the unstable factors of welding current for a long time.

5. It has its own welding current monitoring system, which can monitor the welding current in real time.

6. The spot welding power supply has the function of false welding alarm, which can directly communicate with the motion controller, record the false welding position, and predict and remind the replacement of welding needle.

7. The welding efficiency is about 4 times that of labor, with high stability, labor saving, time saving and cost saving.

| Product Name |

Spot Welding Machine AOT-IST-5000 |

|

Input power (V) |

AC380V ± 10% 50 / 60Hz |

|

Output current (A) |

5000A |

|

No load voltage (V) |

10.8 |

|

Control mode |

Constant current |

|

Cooling mode |

Forced air cooling |

|

Welding conditions |

8 |

|

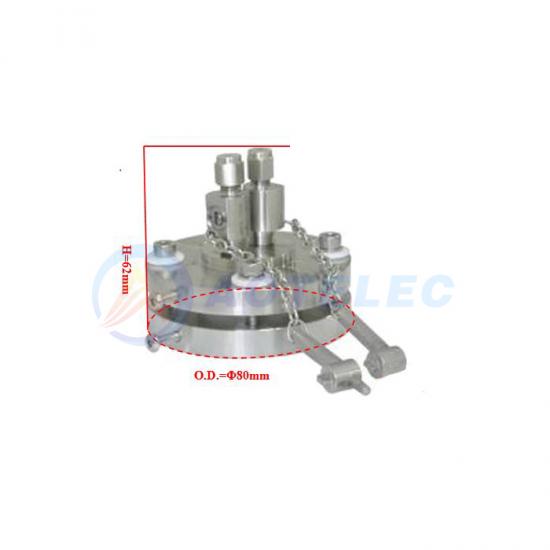

Overall dimension |

W270×H330×D465mm |

|

Transformer size |

W180×H270×D330mm |

|

Application |

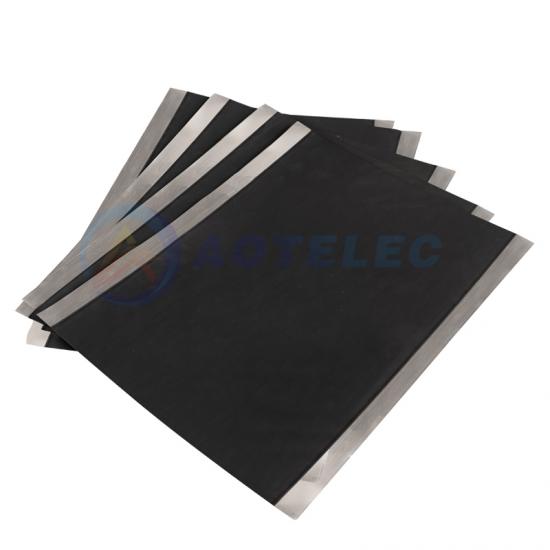

0.15-0.25mm nickel sheet welding |

|

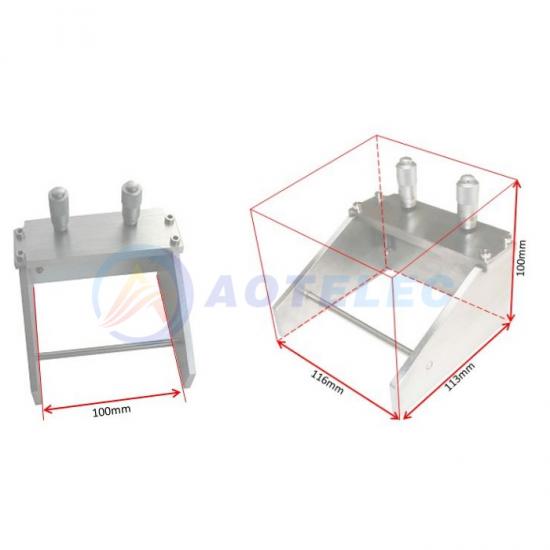

X-axis travel |

0-500mm |

|

Z1 shaft stroke |

0-300mm |

|

Z2 shaft stroke |

0-300mm |

|

Welding head |

Servo motor |

|

Max speed of motor drive |

1500mm/s |

|

Max loaded cell (18650) |

300pcs(20*15) |

|

No. of file groups saved |

99 groups |

|

Operating system |

Motion controller + HMI |

|

Transmission mode |

Spindle servo motor + screw + linear guide rail |

|

Overall dimension |

980L*1260W*1700H (mm) |

|

Welding speed |

0.5 s/point;3000-3600pcs/h |

|

Repeat positioning accuracy |

±0.02mm |

|

Welding thickness |

0.1-0.3mm; Fork or bump above 0.2mm (Nickel Strip) |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported