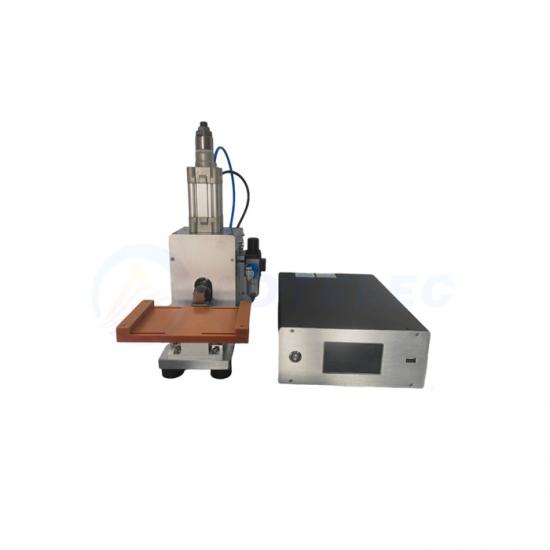

The YDA series uses capacitor energy storage transistors to control the discharge power supply. Since the welding is continued by using the energy stored in the capacitor in advance, it can also be used for small power supply equipment. Controlled by 32-bit microprocessor, digital energy setting, precise control of welding energy, its alarm function can effectively detect welding current, making the welding result stronger and more beautiful, anti-interference design, reliable operation. The unique and excellent characteristics of double-pulse welding can provide better welding quality pulses, using different energy to discharge the welding object twice in a row.

The first pulse removes the dirt on the solder surface and makes the electrodes better align with the base surface, and the second pulse welds the base material, so the welding is firm and beautiful, with less spatter and safe operation. Using precise digital control, 32 groups of parameters can be pre-stored, which can be changed and recalled at will; the color screen LCD can easily display various welding parameters and curves. The discharge time can be precisely controlled, making the solder joints firmer and more beautiful; the minimum division of the welding adjustment time is 10ns, which makes the precision more accurate.

1. Working conditions

1). Power

The input power supply is single-phase mains 200-240V/50HZ (or 60Hz) alternating current, the input current is greater than 10A, and there must be a ground wire and a reliable grounding.

2). Temperature

The transistor welding machine is a high-precision welding equipment, and the transistors inside are greatly affected by temperature, so the equipment is not suitable for working in an environment of 0-40°C, and the recommended working temperature is room temperature.

2. Electrical parameters

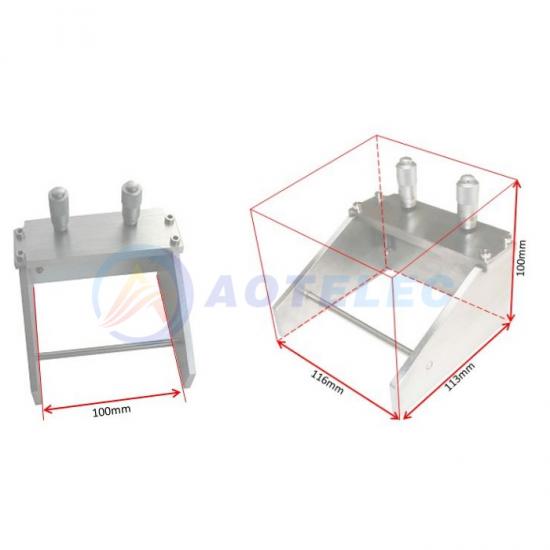

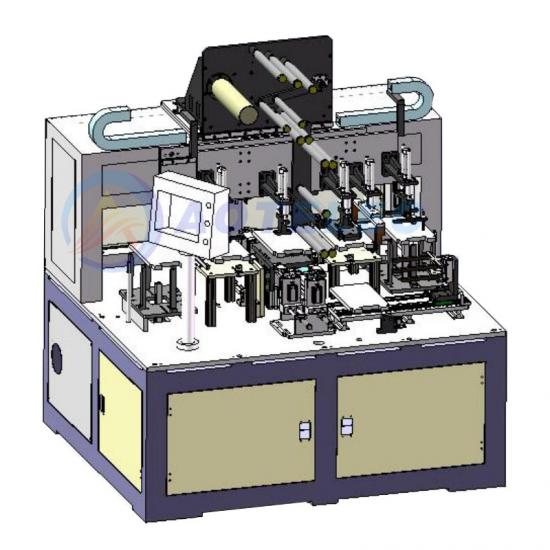

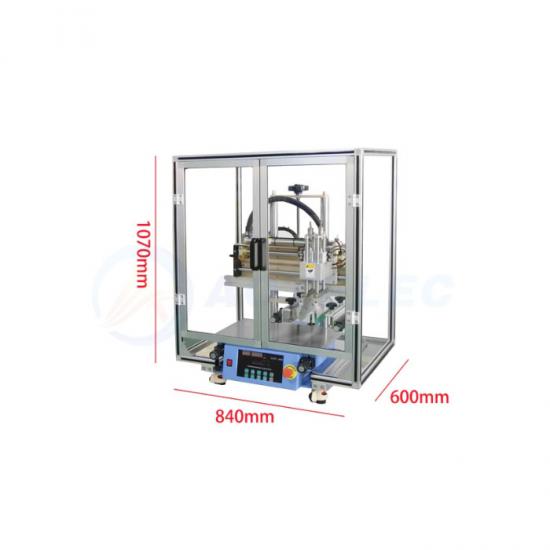

4. Equipment layout and dimensions

4.1 Whole machine diagram

4.2 Power Diagram

5. Technical parameter

5.1 Equipment operating parameters

5.1.1 Input voltage: AC220V-240V±10% 50Hz-- 60Hz Rated power: 350W 5.1.2 Maximum

Output current: 9.99KA

5.1.3 Control mode: constant current, constant voltage, current-voltage mixed voltage control

5.1.4 Current setting: 0.50-9.99KA

5.1.5 Voltage setting: 0.1-9.99V

5.1.6 Monitoring range setting: Current 0.00-9.99KV Voltage: 0.00-9.99V

5.17 Accidental electricity detection function: yes

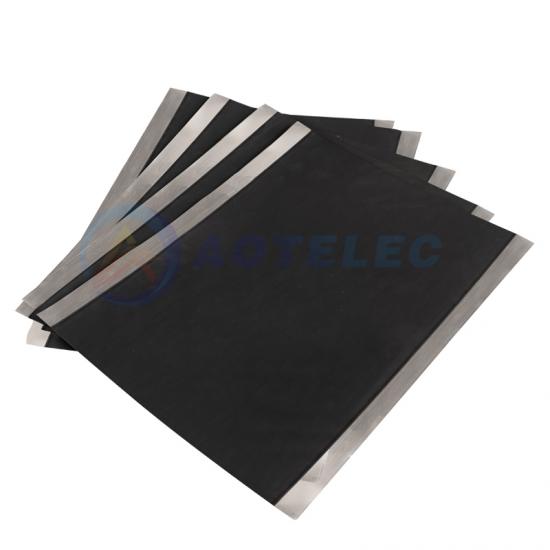

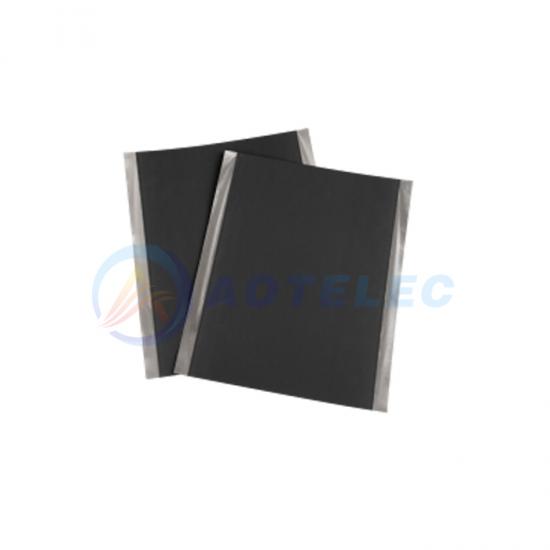

5.1.8 Suitable thickness of flat welded nickel sheet: 0.08-0.25MM nickel-plated steel/pure nickel (depending on the material and process of nickel sheet)

5.1.9 Applicable thickness of pit welded nickel sheet: 0.15-0.3MM nickel-plated steel/pure nickel (depending on the material and process of nickel sheet)

5.2.0 Dot count: 0-99999

5.2.1 Repeated energization speed: refer to the usage curve rate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported