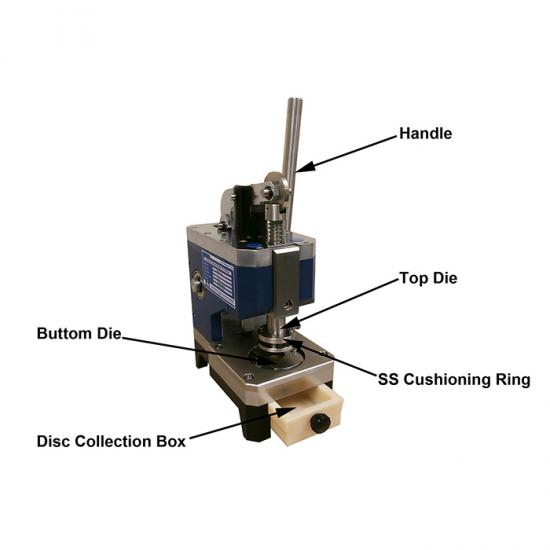

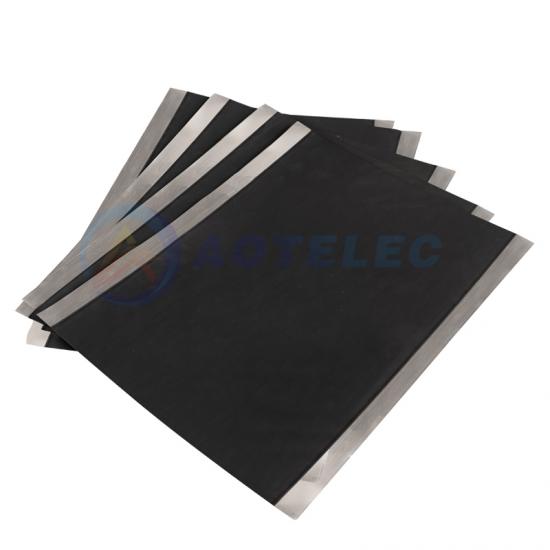

AOT-MSK-T-06 is a precision disc cutter with max. the pressure of 600kN. This tool is manually operated and is designed for cutting round discs from a thin metal sheet/foil in the range from 0.01 mm to 0.10 mm (such as Cu, Al, and stainless steel ). The resulting discs can be used as electrode/separator discs of the split test cell and coin cell for battery researchers.

The disc cutter comes with 4 cutting dies in 12, 15, 19, and 20mm.

SPECIFICATIONS:

|

Max. Nominal Pressure |

600 kN |

|

Max. Stroke |

40 mm |

|

Max. cutting thickness |

200 microns |

|

Hole Diam. for upper mold insert |

12mm |

|

Cutting Dies |

Four sets of cutting dies (12, 15, 19, 20 mm) are included in the standard package, which is made of hardening tool steel 15mm (for electrode discs of CR20xx series coin cell cases) 19mm (for electrode discs of CR20xx series coin cell cases and CR2325 negative side cases) 20mm (for electrode discs of CR2450 cell cases, CR2325 positive side cases, and separator discs of CR20xx series coin cell cases) Optional sizes available in 10, 12.7 (1/2''), 16, 18, 24 mm diameter at extra cost. 24mm (for electrode and separator discs of CR24+ cell cases.) |

|

Cutting thickness |

0.01 mm - 0.10 mm for all type material with hardiness < RC 40 mm Note: Thicker foil will result in the shorter the life of the die |

|

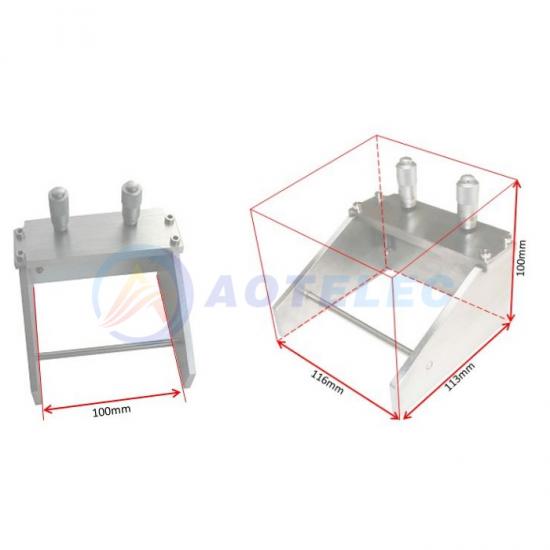

Product Structure and Dimensions |

· The base is made of cast iron · Dimension: 230mm(L) x 190mm(W) x 450mm(H)

|

|

Warranty |

One-year limited manufacturer warranty with lifetime support No warranty for die set caused (*Rusted and damaged parts due to improper storage condition or maintenance are not covered by warranty) |

|

Net Weight |

39kg |

|

Application Notes |

If you are going to make CR2016, CR2025 or/and CR2032 coin cell batteries, you will need at least three cutting dies: 15mm (for negative side case, which is 16.5mm in diameter) 19mm (for positive side case, which is 20mm in diameter) 20 mm (for the separator to fully separate the electrodes in both negative and positive cases) For CR2450 coin cell, a 20mm cutting die can be used for cutting electrode discs and the 24mm cutting dies for either electrode or separator discs. 24 mm (for electrode and separator discs in CR24+ series or depending on customer's requirement) For cutting separator films, it is necessary to use transparent file covers to sandwich the film prior to cutting. This setup will stiffen up the film for ensuring smooth cuts on the edges of the disc. Warning: You must pay great attention to change die from one size to another. Mis-alignment will result in die damage. Please read the operation manual carefully when changing the die. |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels,

enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative Profile

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

Q5:What's the warranty for the items?

A: We are very confident in our products, and we pack them very well, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately. Warranty for equipment is 1 or 2 year (12 or 24 months depends on the type of products), If the equipment parts are damaged due to non-human factors within one year, we will provide replacement parts free of charge.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported