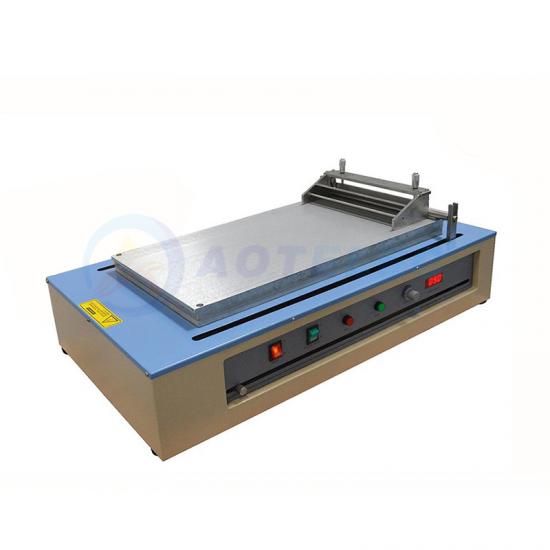

MSK-AFA-PD200 flatbed coating machine, equipped with extrusion coating mold, linear plunger feeding, minimum material loss of about 18ml, maximum coating size of 200x300mm, can be used in a glove box, suitable for low viscosity less than 1000mPa. s, coating thickness accuracy of ± 1 μ m, can be optionally coated with scraper, wire rod, and four sided mold maker.

It is an ideal tool for studying hot melt films of polymers or polymer composite materials, such as plastic films, flexible electrodes for solid-state batteries, perovskite solar cells, and thermoelectric sheets.

Functional Features:

Chip extrusion coating, with high coating accuracy and good consistency;

Suitable for low viscosity coatings and thin coating processes;

Low demand for coatings and substrates, easy to use, suitable for process validation;

Coated substrate with vacuum adsorption function, standard vacuum pump;

Can be used inside the glove box;

Multiple coating processes can be optionally selected;

Optional wind knife module for perovskite coating;

Special coating plates can be selected for membrane coating;

|

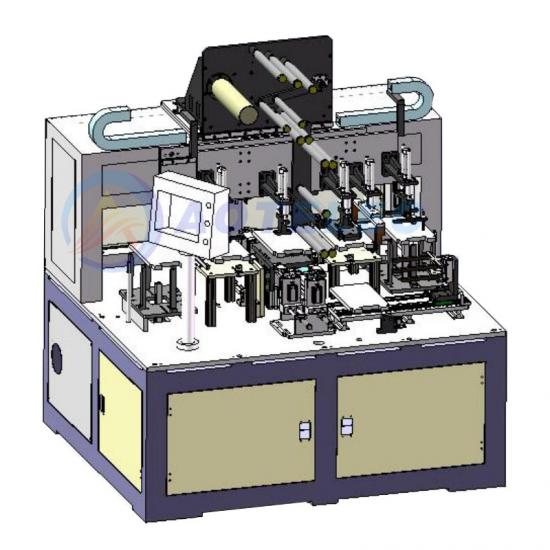

Product Name |

Slot Die Sheet Coating Machine |

|

Power |

Single phase AC110-20V ± 10%, frequency 50/60Hz, power 300W |

|

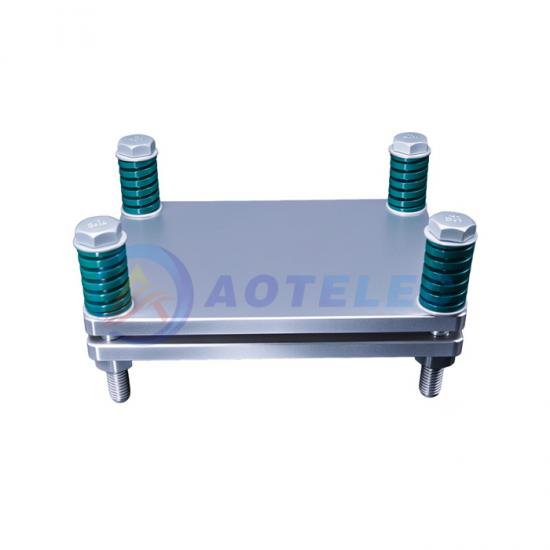

Coating method |

extrusion coating |

|

Coating thickness |

± 1 µ m (reference graphite carbon slurry, viscosity ≤ 1000mPa. s, solid content 5%, coating dry thickness ≤ 5 µ m) |

|

Type |

Single layer coating |

|

Chamber |

semi-circular single chamber |

|

Coating width |

Max.200mm |

|

Mold feeding speed |

Mold feeding speed |

|

Mold head movement |

0.5-20mm/s (extrusion coating head movement speed) |

|

Mold head adjustment range |

0-5mm |

|

Adjustment method |

manual adjustment with micrometer, display accuracy of 1 μ m |

|

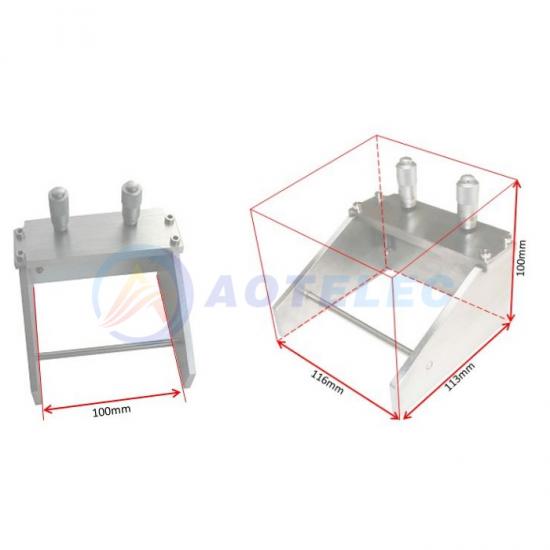

Coating size |

Max L300xW200mm |

|

Substrate size |

L360 * W250mm |

|

Equipment size |

L759 * W518 * H425mm |

|

Weight |

110KG |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported